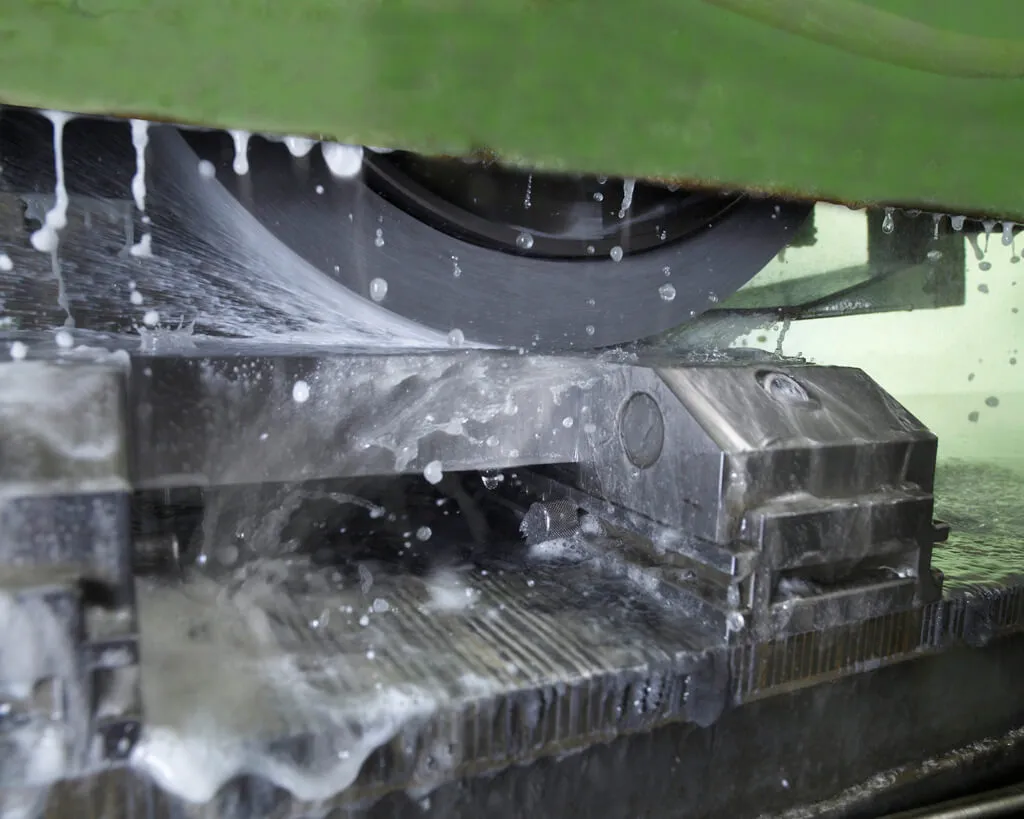

CNC flat grinding

Fine grinding:

- Width: max. 1,000 mm

- Height: max. 550/800 mm

- Length: max. 4,000 mm

- (depending on machining requirement)

Stöckel precision grinding machine, hydrostatic guides in all three axes, all main elements in measuring machine granite for optimum accuracy

Precision sine table with magnetic clamping plate 500 × 2,000 mm for accurate angle grinding, spindle drive up to 75 kW, conditioned cooling water

Cross grinding with grinding segments:

max. 600 × 6,200 mm with Ra = 4 μm (depending on material and component), precision angle swivel magnet +/- 92° up to 300 × 3,100 mm, max. Ø 1,200 mm with Ra = 4 µm for round parts, rings or mass production parts.

The machine data reflects typical and maximum values. In total, we deploy over 20 grinding machines with a table load of up to 3,000 kg and machining surfaces of between 500 × 1,000 mm and 1,000 × 3,060 mm and with cross grinding up to 600 × 6,200 mm. The total grinding surface amounts to more than 30 m²!

In achieving the high levels of component quality, however, not only is a high level of machine accuracy crucial but above all the experience and skill of our workforce in the precise setting of the work piece by hand.

Over 80 people take great pains in tending to your work pieces at the Recknagel factories in Hückeswagen and Christes.

Contact: schleifen@stahlnetz.de

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.