CNC profile grinding

Mägerle MFP

- Width: max. 650 mm

- Height: max. 550 mm

- Length: max. 2,600 mm

- (depending on machining job)

CNC measuring

Zeiss UC 850

- Width: max. 850 mm

- Height: max. 600 mm

- Length: max. 2,400 mm

Spindle drive: 75 kW, water cooled, conditioned cooling water with vacuum high-performance fine filtration plant

CNC controller: Siemens 840 D

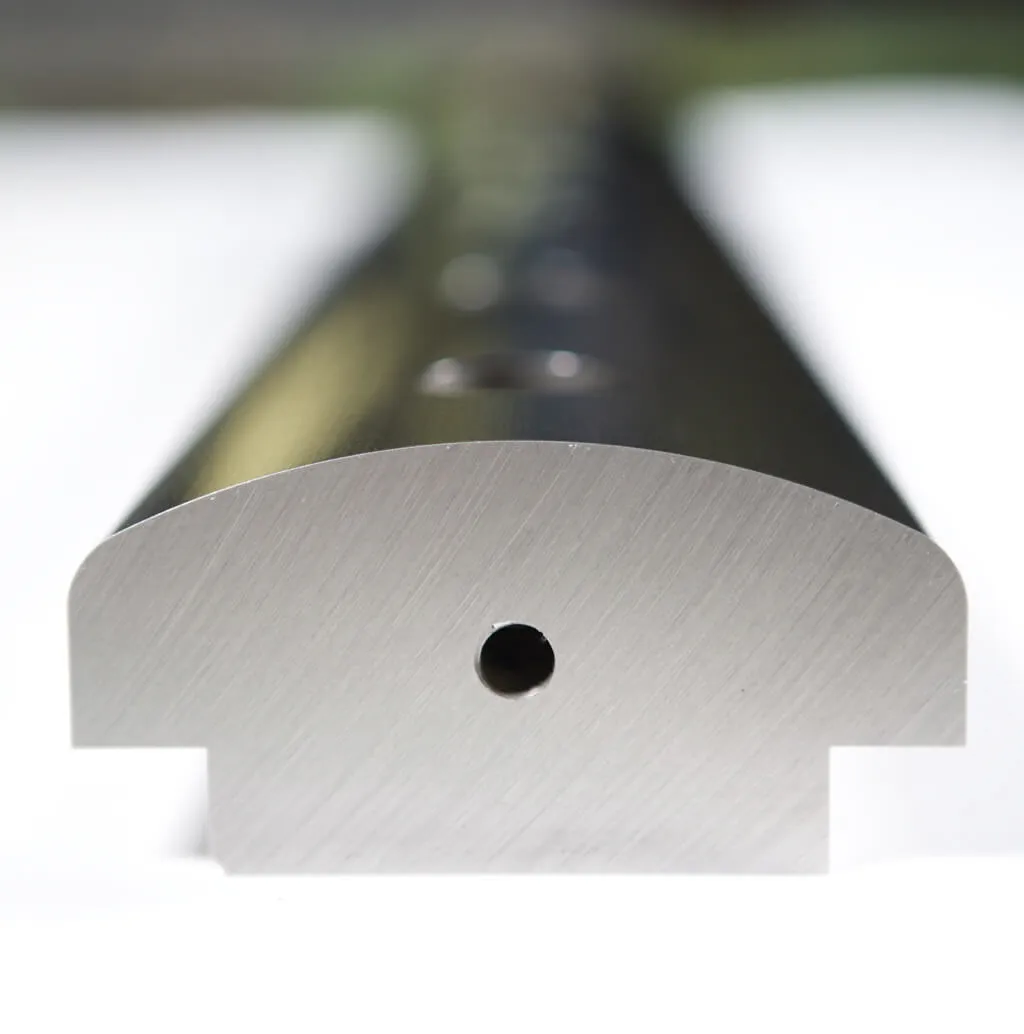

We have several Mägerle MFP high-performance grinding machines on which we grind components to the highest level of precision, up to 2,600 mm in length depending on machining job.

In addition to profiles, due to the machines' contour controlled longitudinal axis, radii, gradients and, for example, lead-in bevels with transitional radii can be manufactured precisely.

Non-wearing hydrostatic guides permit the highest levels of accuracy, in particular when using the very low-distortion, modern materials Toolox 33 or Toolox 44.

Due to the high drive capacity of 75 kW at the spindle and flexible profiling with the diamond form roller, both one-offs and large series can be manufactured economically.

You will receive an optimum quotation from us when you provide us with the contour data as a CAD file for adoption into our CNC programming system: schleifen@stahlnetz.de

Reap the benefit of our excellent options for your demanding jobs.

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.