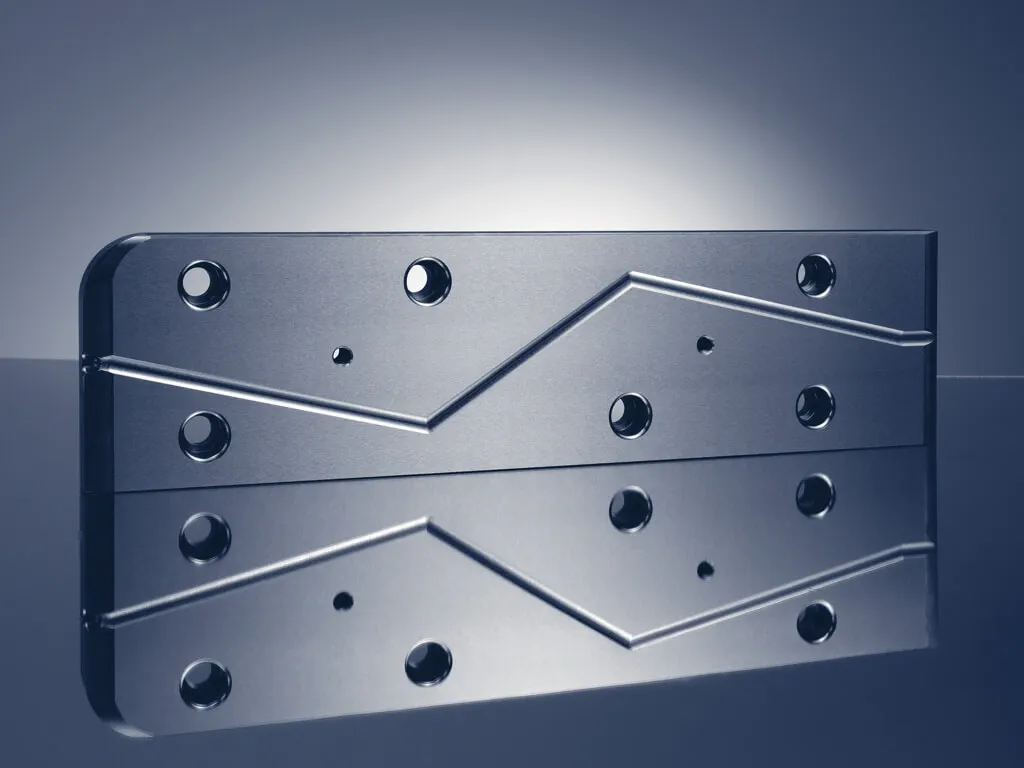

Guiderails

Hardened precision guiderails, as the quality-determining element in machine construction, are our traditional core product. Recknagel is distinguished through over 40 years experience as manufacturer of high grade machine parts to individual customer designs.

From a broad range of ideally suitable steels in combination with the appropriate heat treatment, we produce a high quality product for your demanding applications. Precision in steel means the closest dimensional, form and positional tolerances.

We like to pass on our experience and will be happy to suggest the most suitable tool steel and appropriate heat treatment process for your design. We produce work pieces is series or even small batch quantities from one-offs upwards depending on the requirement, design and scope of application of your guiderails.

For roller guides we recommend hardnesses from 58 HRC, through-hardened as a rule. With linear guiderails, our TOOLOX® 44 material is a very interesting alternative, with nitrided surface (800-900 HV 5 64-67 HRC) as required. We can, of course, also supply both inductive or case-hardened components.

Our standard parallelism is 0.01 mm/metre, the standard surface finish with fine grinding is Ra = 0.8 μm. μ-precise guiderails are possible depending on design.

We produce fine ground, hardened precision guides up to 3,000 mm in length and cross-ground hardened guides up to 4,000 mm. Long guiderails should be divided. End faces ground to the exact angle facilitate sequential assembly.

With machining surfaces up to 1,000 mm × 3,000 mm we can fine grind several guides in one set. With through-hardened components, a change in length in the range of +/- 1 ‰ in terms of the measured length is not always technically avoidable and should be taken into account in the design.

Hard boring is possible at hardnesses up to 62 HRC for the most precise hole spacings. Thanks to the latest CNC grinding technology with up to 75 kW spindle capacity, we can execute accurate radii, profiles, gradients etc. with high level productivity and precision.

Contact: rps@stahlnetz.de

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.