1.7131

Steel Glossary

1.7131 5115/527 A 19

Chemical Composition %

| C | Si | Mn | Cr | |

|---|---|---|---|---|

| max. | 0.19 | 0.4 | 1.3 | 1.1 |

| min. | 0.14 | 1.0 | 0.8 |

Case-hardening steel for the production of highly stressed and wear-resistant components of all kinds.

You can obtain this material from us as precision flat steel custom-made, EcoPlan, VarioPlan, VarioRond, and as raw material cut to size.

You can also get 1.7131 from us, tailored to your specifications, as a machine part or as a pre-heat-treated guide rail.

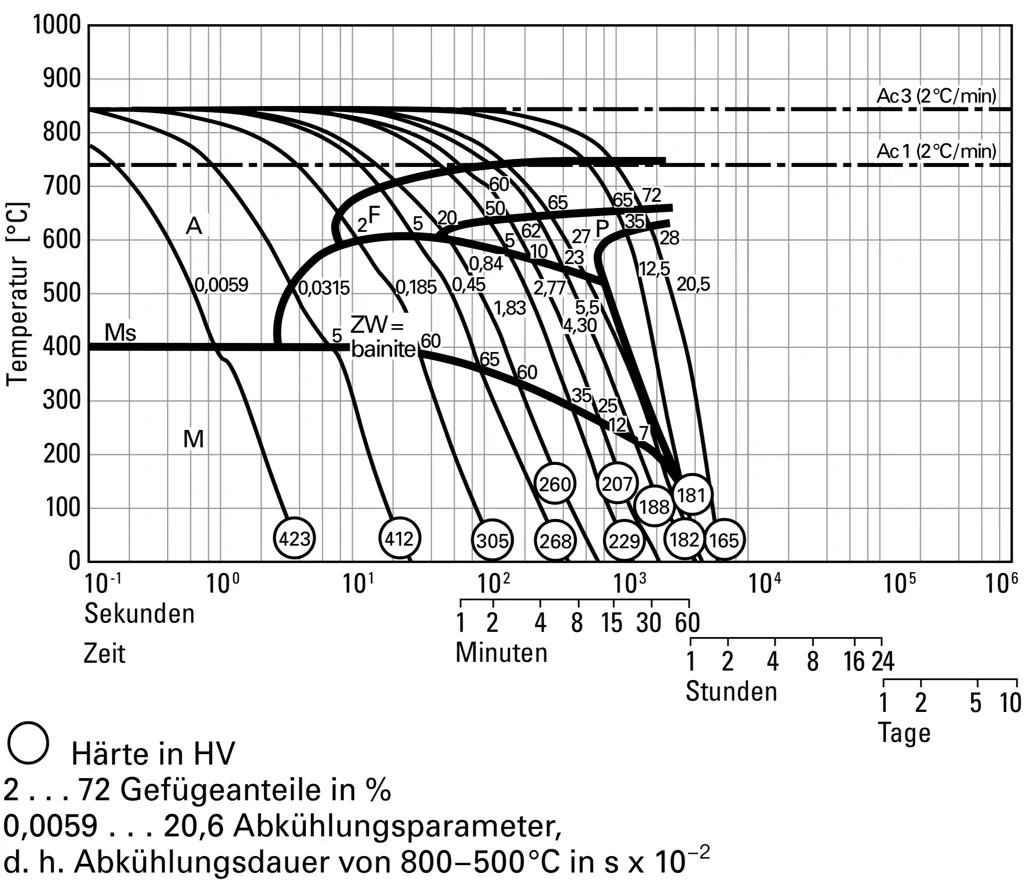

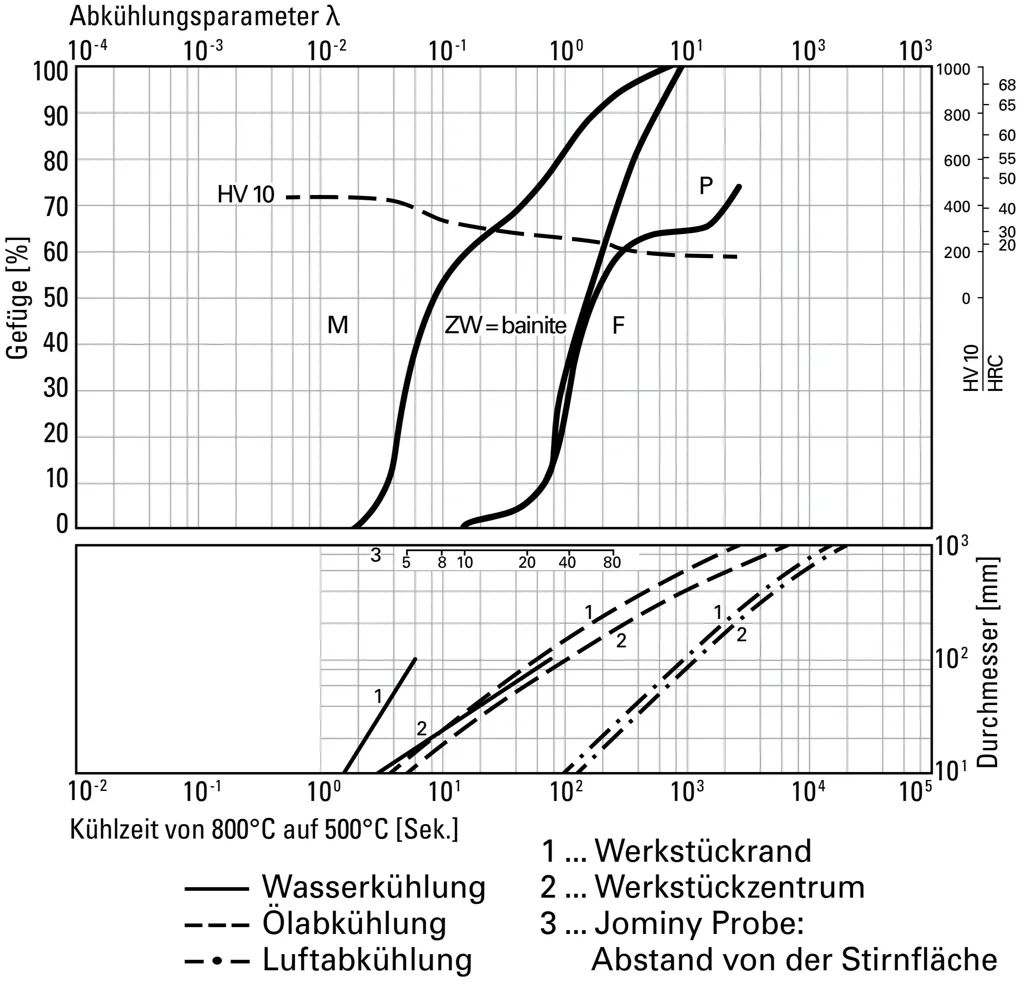

Continuous Cooling Transformation Diagram

Austenitization Temperature: 870°C, Holding Time: 10 Minutes

Microstructure Phase Diagram

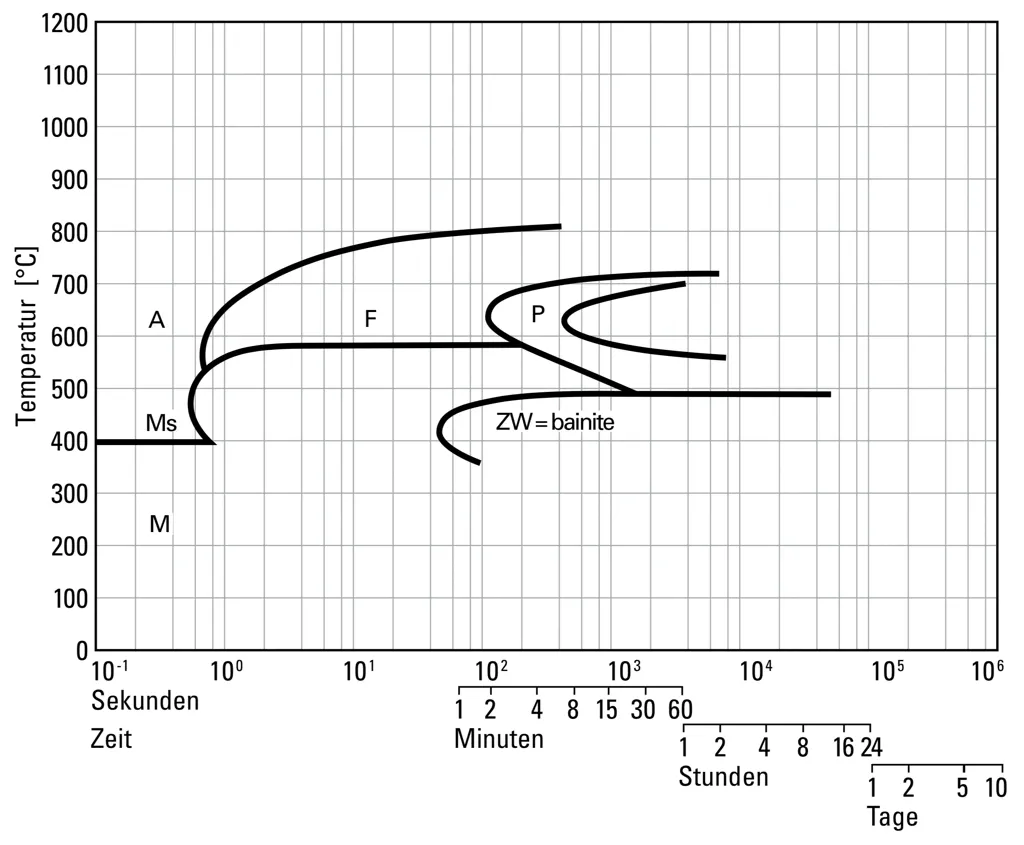

Isothermal Time Temperature Transformation Diagram

Austenitization Temperature: 870°C, Holding Time: 10 Minutes

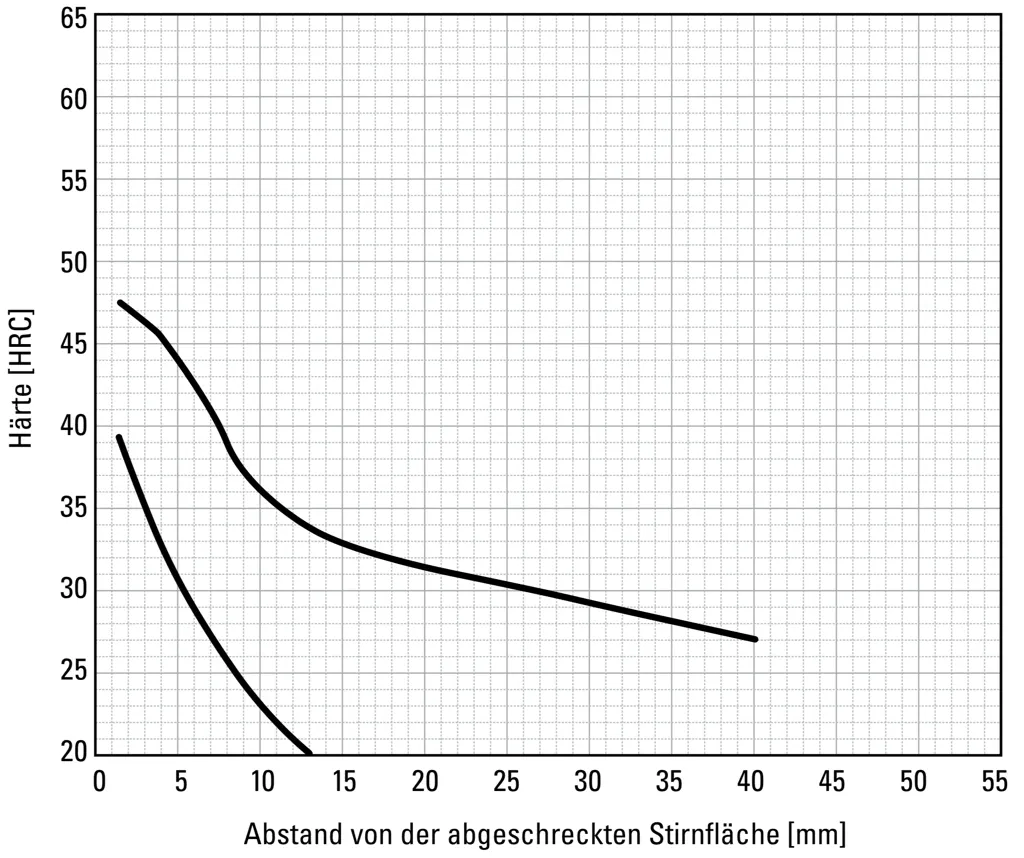

Jominy End Quench Test

Hardening Temperature: 870°C

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.