Steel Glossary

Daido NAK80

| C | Si | Mn | Cr | Mo | Ni | Al | Cu | |

|---|---|---|---|---|---|---|---|---|

| Typical Composition (Weight %) | 0.12 | 0.3 | 1.5 | 0.3 | 0.3 | 3.2 | 1.0 | 1.0 |

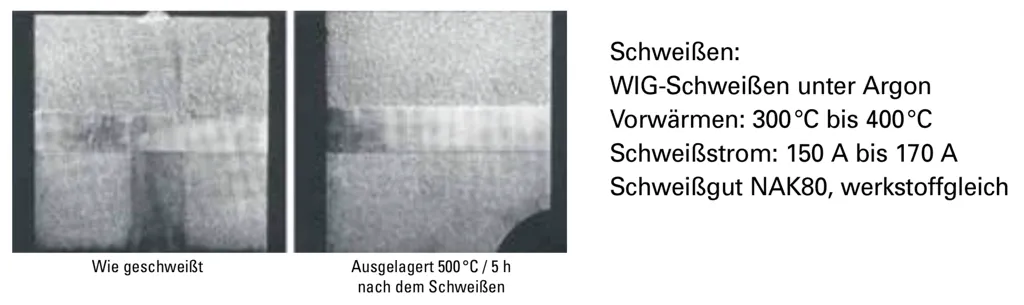

Mirror-polishable plastic mold steel, pre-hardened to 40 HRC. The vacuum remelting process ensures the highest purity of this steel. It is weldable with the same alloy, and subsequent post-weld heat treatment results in a homogeneous microstructure with uniform hardness without a heat-affected zone.

NAK80 is used for manufacturing plastic molds with large cross-sections and very high requirements for polishing. It has proven particularly effective in molds for headlights, bumpers, dashboards, and generally molds for visually demanding parts. NAK80 is suitable for thermosetting plastics and thermoplastics. Fiber-reinforced plastics usually require a PVD coating.

NAK80 is a trademark product of the Japanese manufacturer Daido Steel. Gebr. Recknagel distributes NAK80 as the exclusive stockholding sales representative for Central Europe.

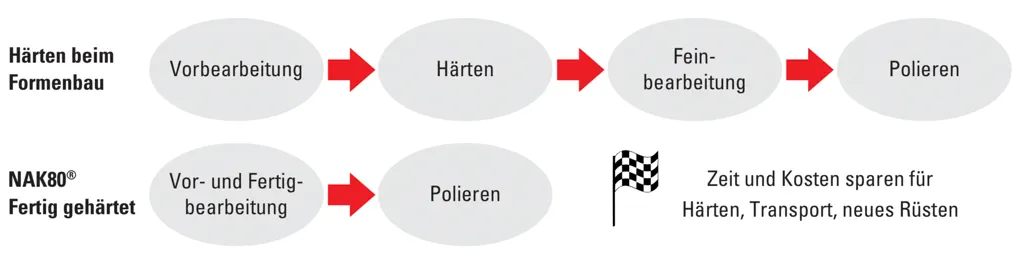

Save Time and Costs:

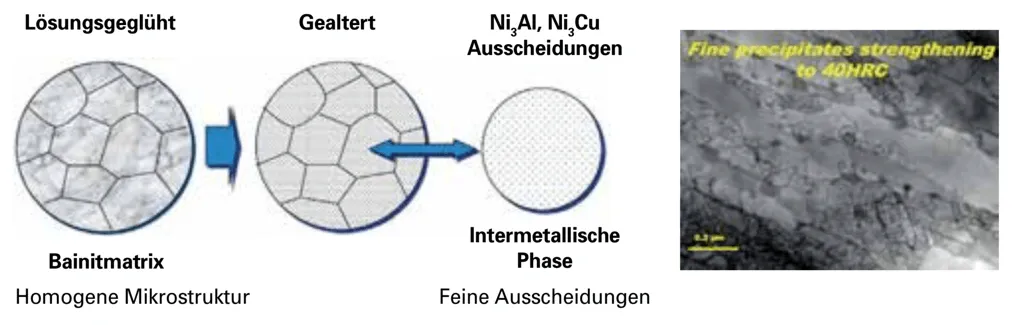

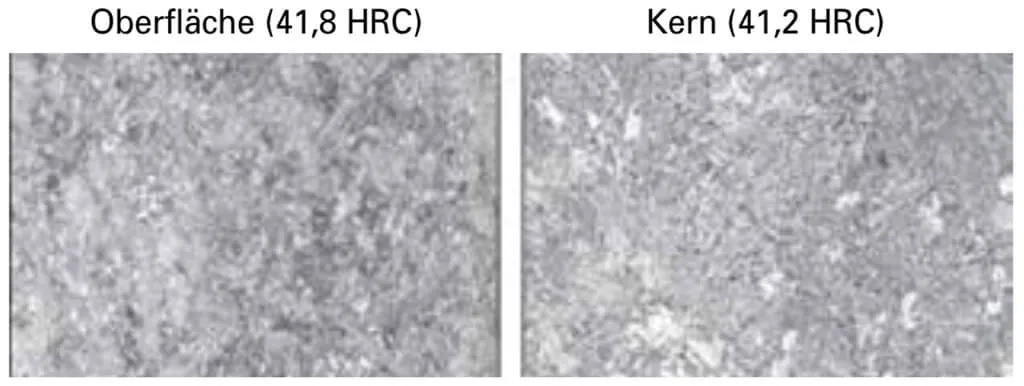

Microstructure:

Excellent Polishability

Seamless Weldability

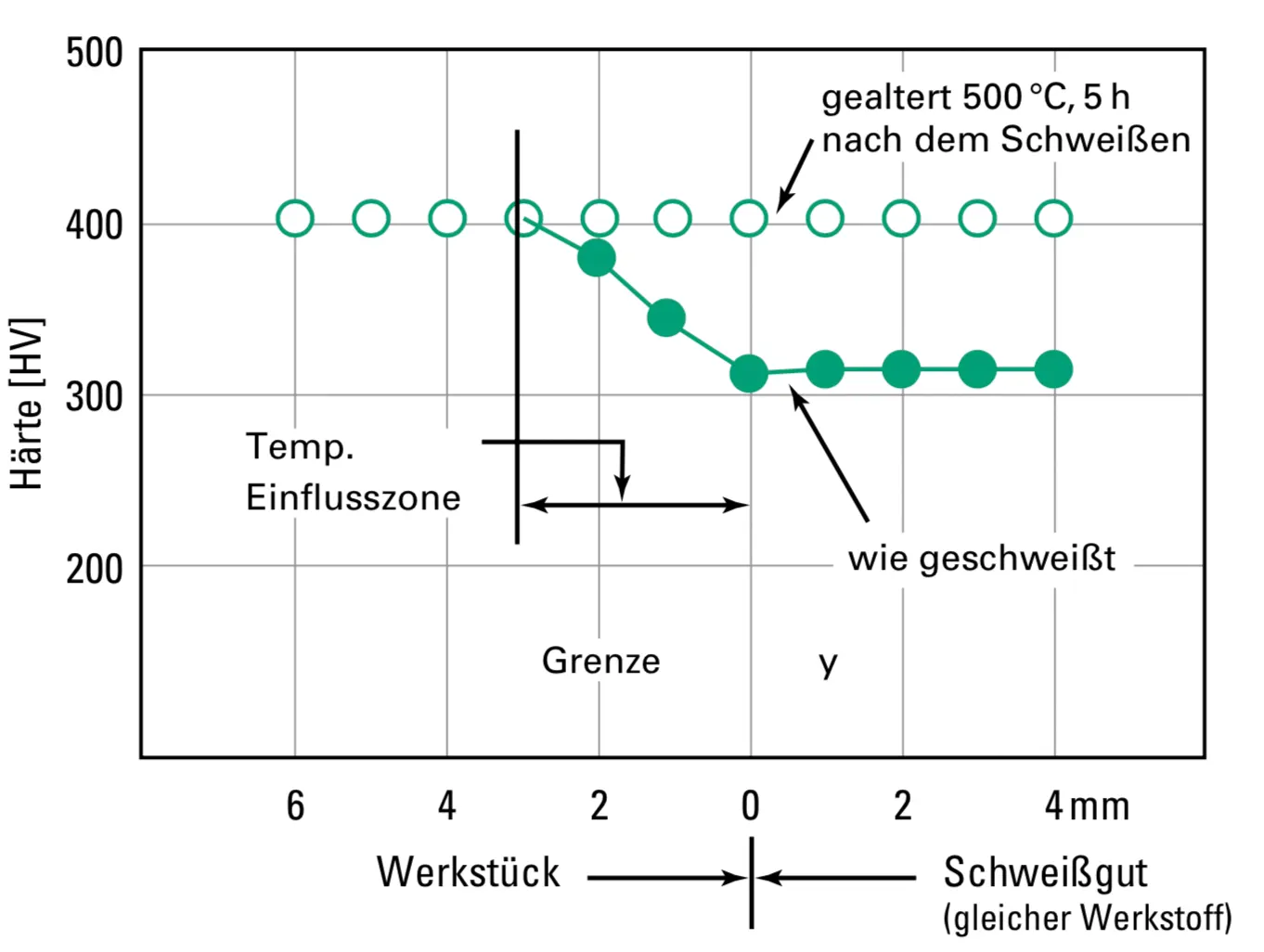

Typical Hardness Distribution after Welding NAK80

No hardness differences after welding when subsequently post-weld heat treated.

Excellent Machinability

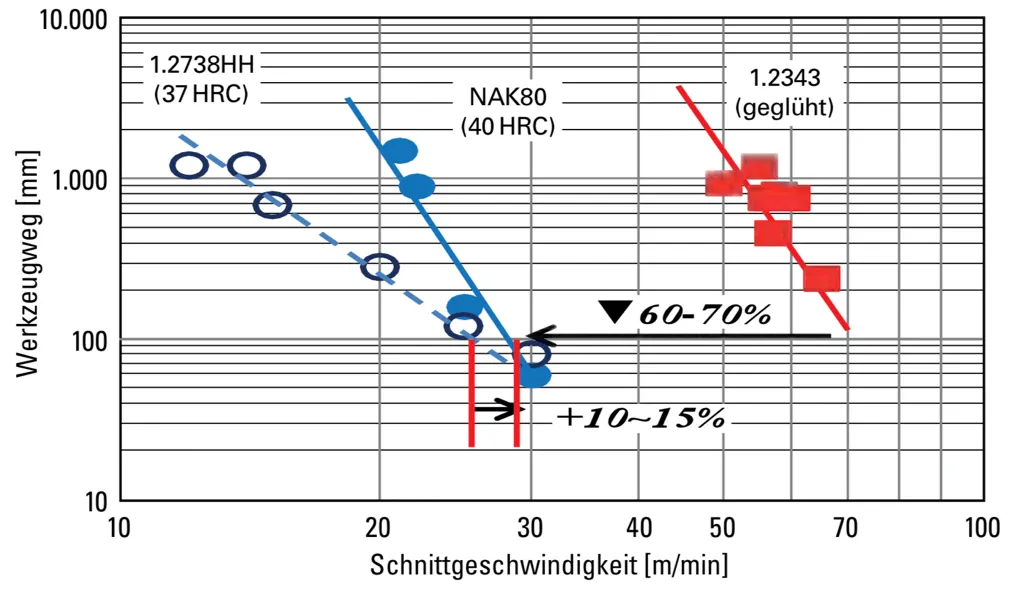

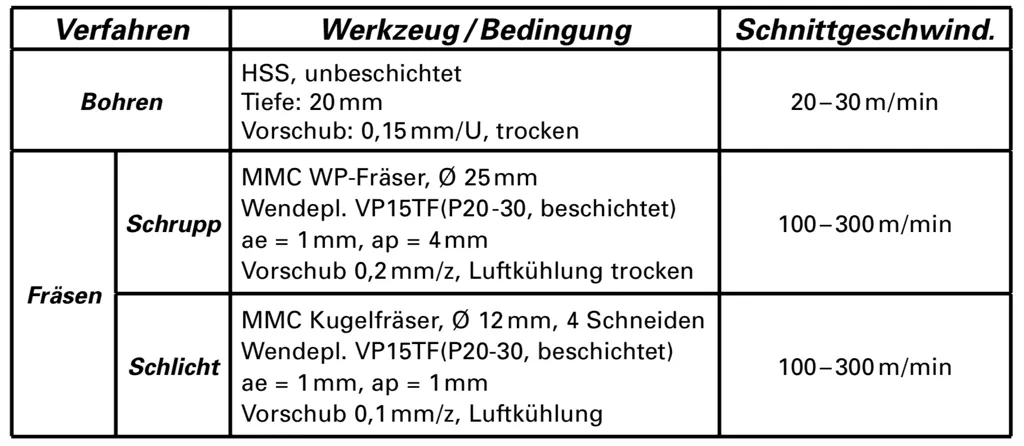

Drilling

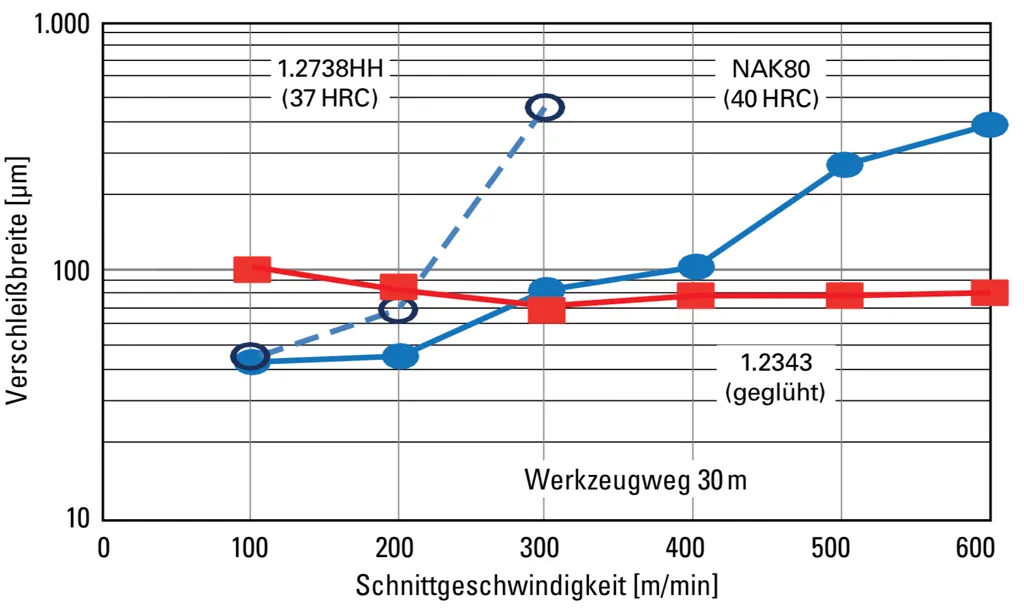

Rough Milling

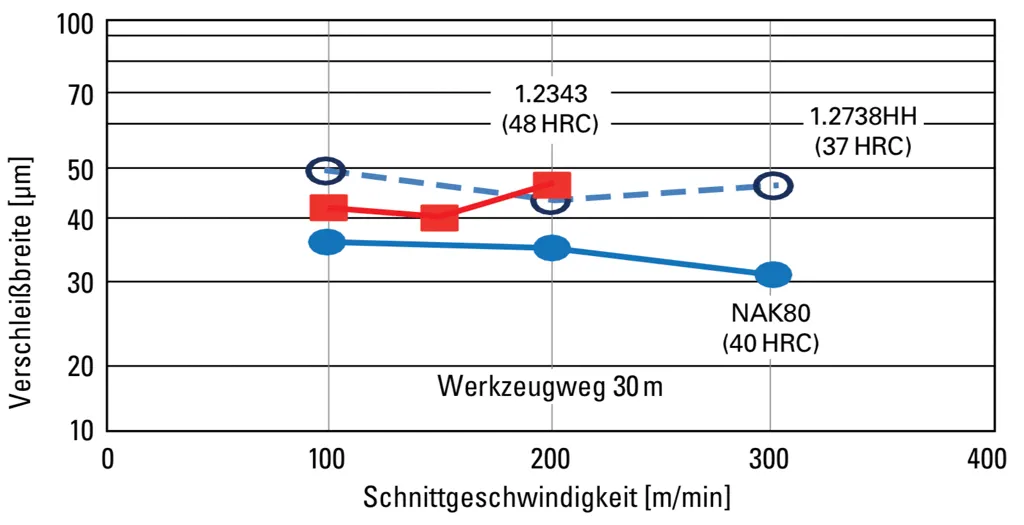

Finish Milling

Cutting Data Recommendations NAK80

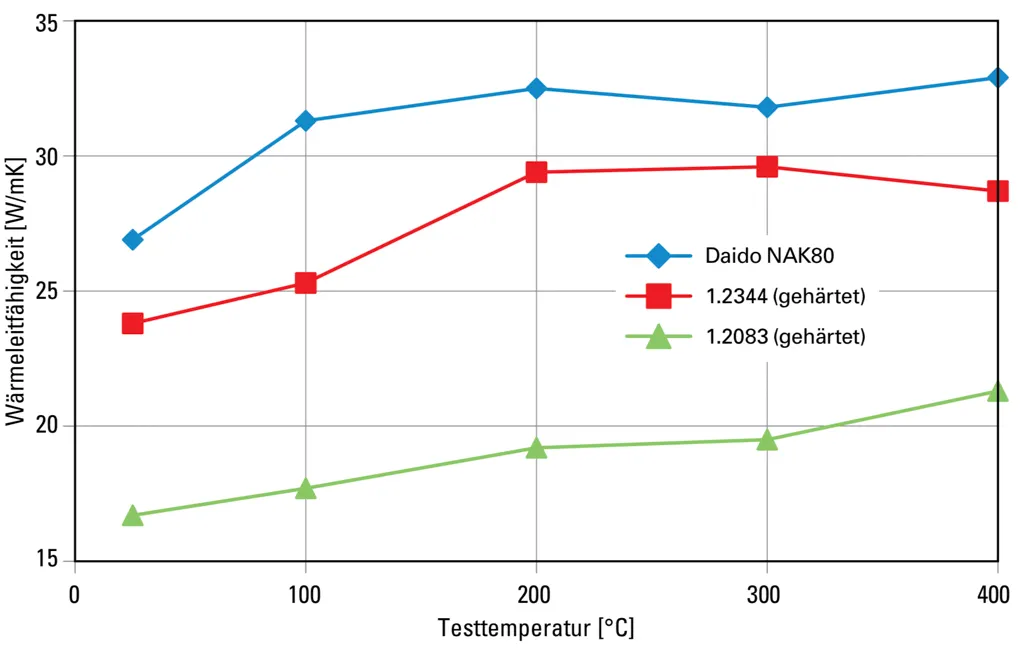

Thermal Conductivity

NAK80 demonstrates a high thermal conductivity due to its particularly favorable alloy composition, resulting in shorter cooling times.

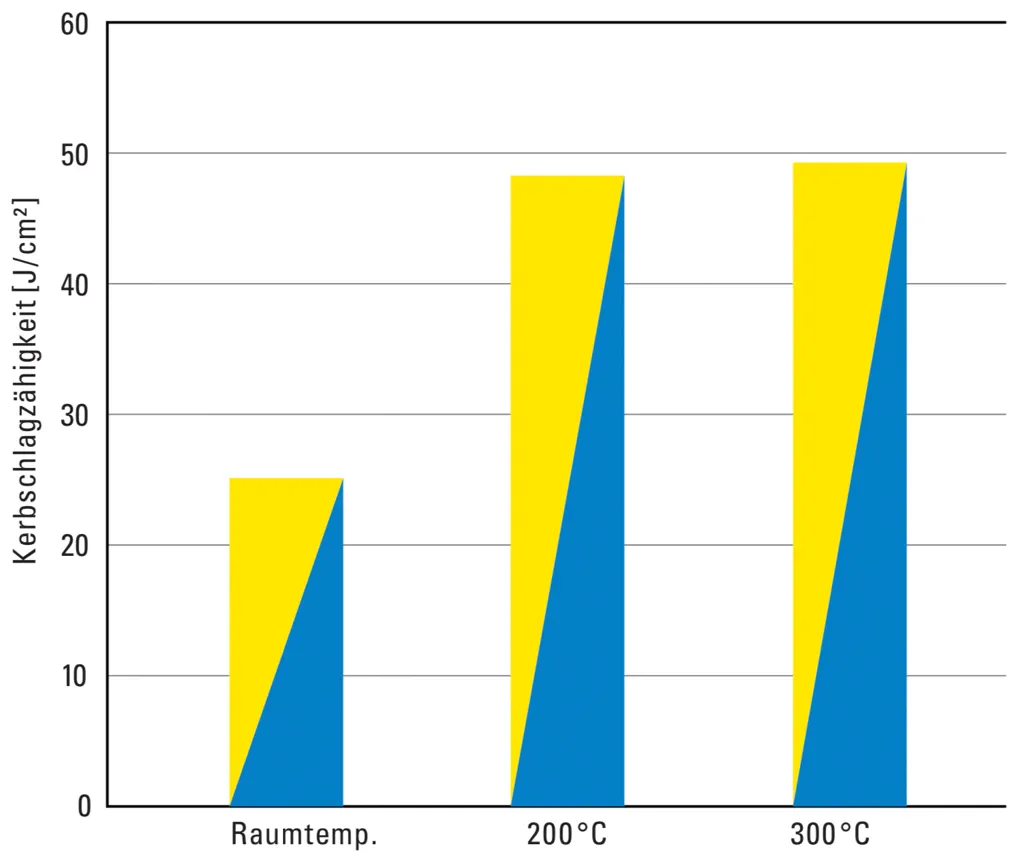

Impact Toughness

Notched U-Shaped Test

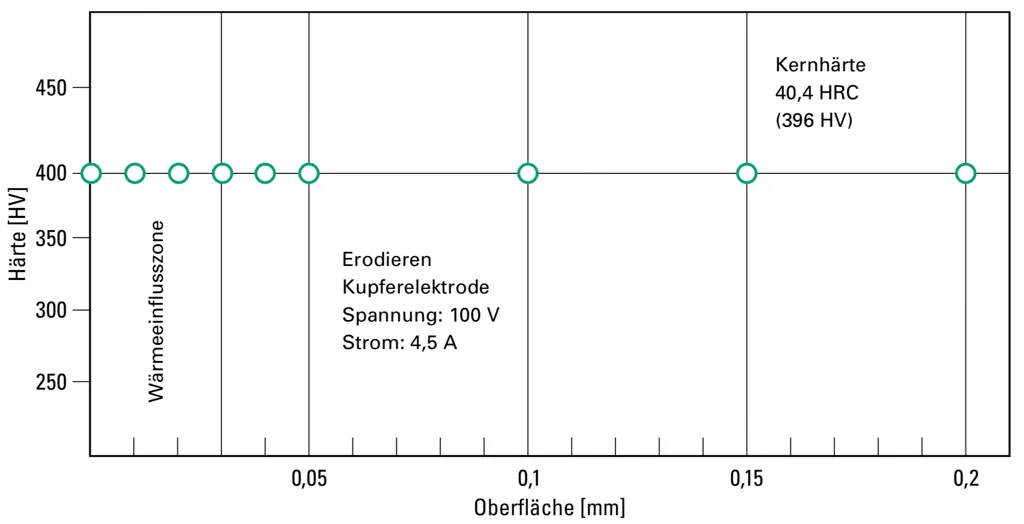

EDM (Electrical Discharge Machining)

Easily perform fine electrical discharge machining without an increase in hardness of the machined surface.

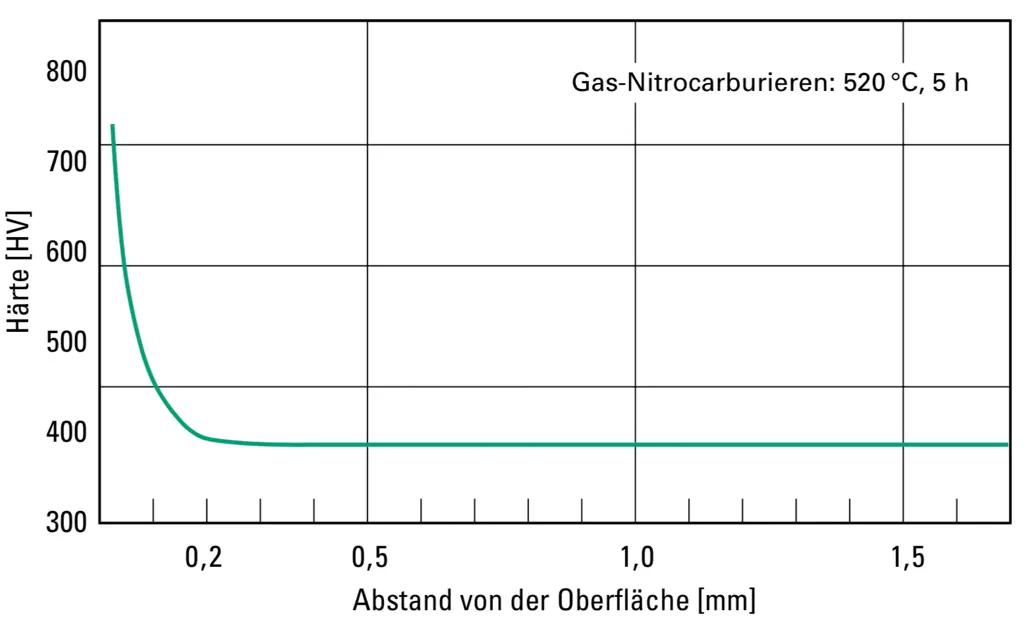

Nitriding

Hardness reduction and/or distortion may occur with any treatment above 520°C.

Mikrostrukture

The provided values are always representative technical data based on our investigations. If not otherwise stated, they do not constitute guarantees. Please seek individual consultation for specific cases.

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.