Steel Glossary

1.2343 H 11/BH 11

AISI H11, BS BH11, AFNOR Z 38 CDV 5

| C | Si | Mn | P | S | Cr | Mo | NI | V | |

|---|---|---|---|---|---|---|---|---|---|

| max. | 0.41 | 1.2 | 0.50 | 0.03 | 0.02 | 5.5 | 1.5 | 0.21 | 0.5 |

| min. | 0.33 | 0.8 | 0.25 | 4.8 | 1.1 | 0.3 |

Hot work steel for the production of highly stressed hot work tools, warm forging dies, die-casting tools, hot shear blades, and forming dies.

You can obtain this material from us as precision flat steel (standard and custom dimensions, VarioPlan, VarioRond, and as raw material cut-to-size.

1.2343 is also available from us as a custom-made machined part according to your specifications.

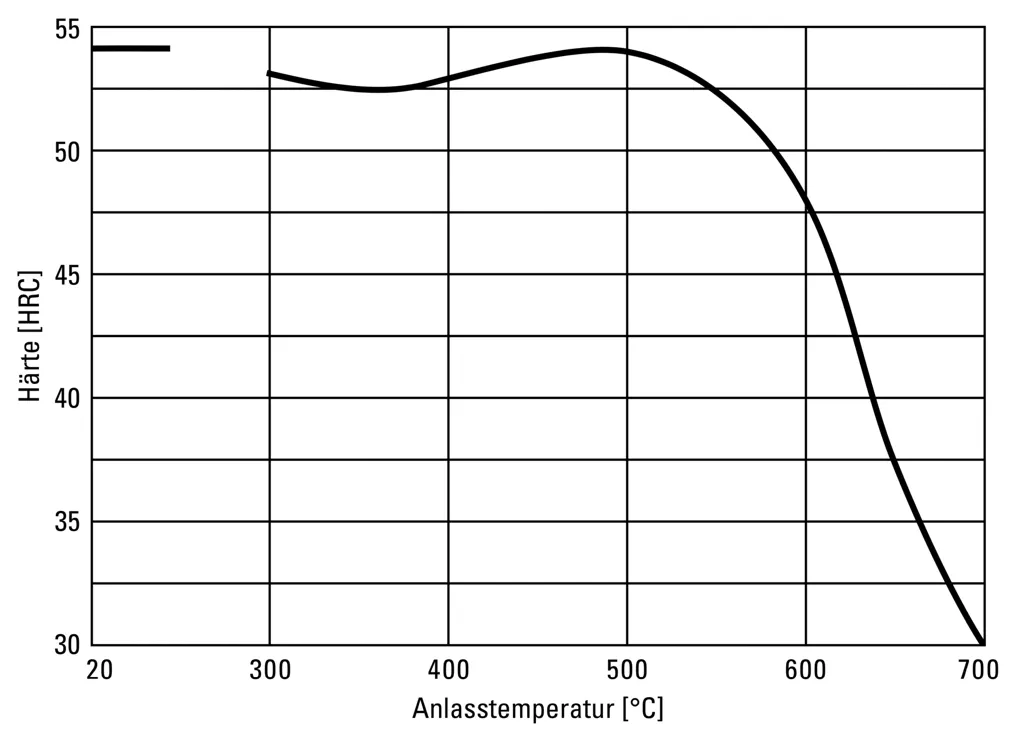

Tempering Chart

Hardening Temperature: 1020°C, Cross-Sectional Sample: Square 50 mm

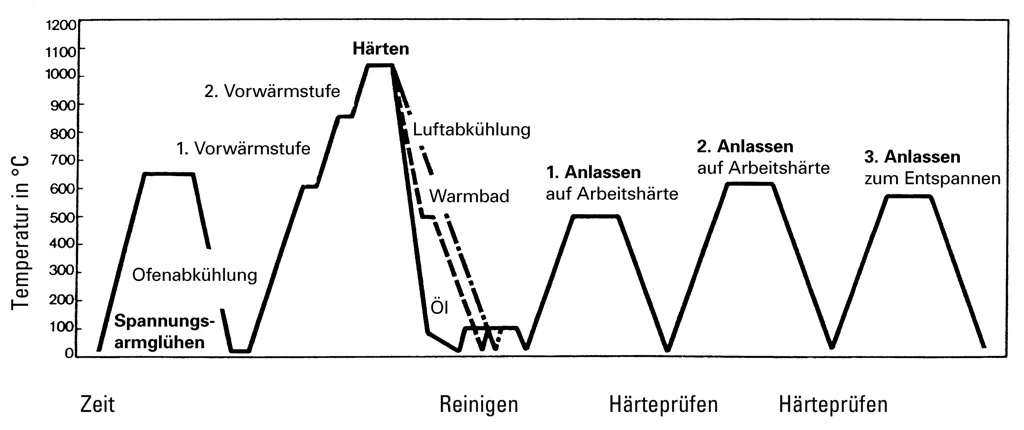

Heat Treatment Schedule

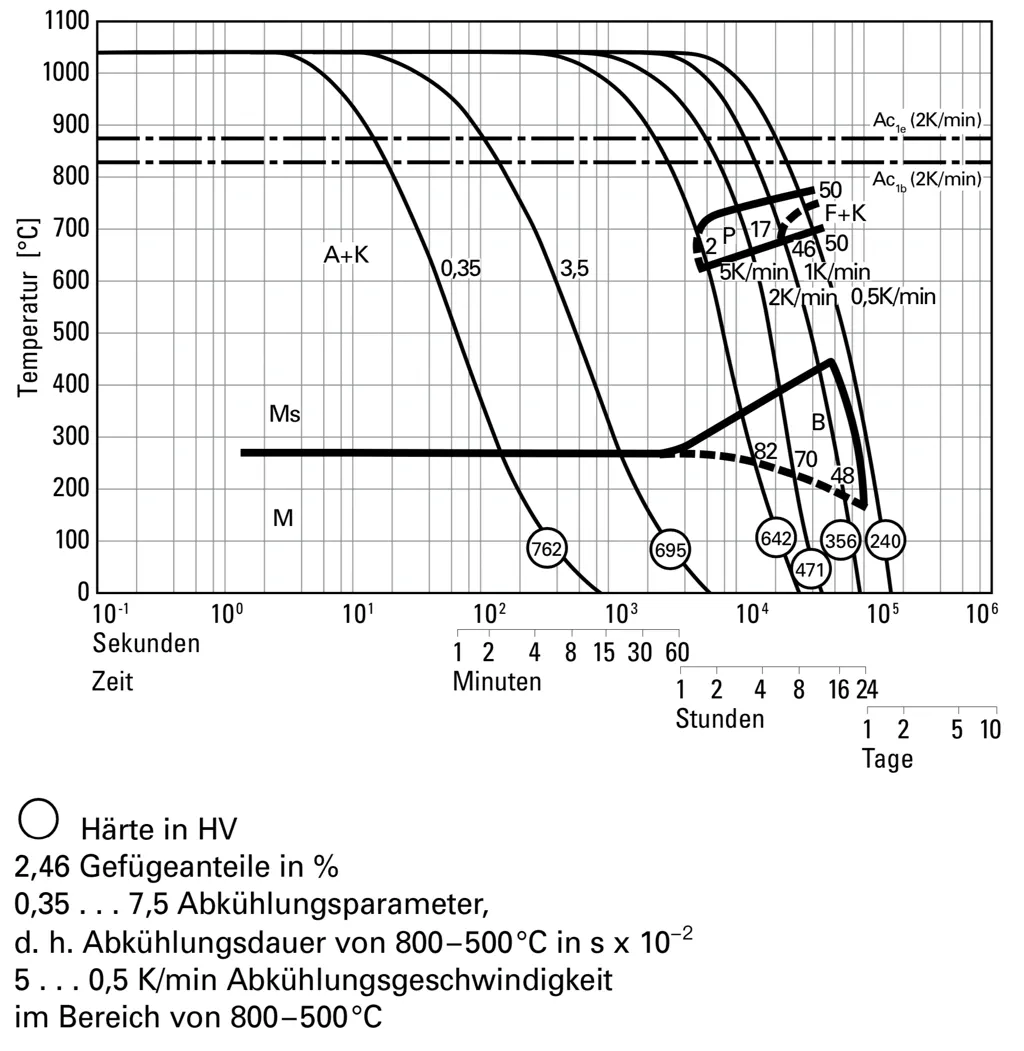

Continous Cooling Transformation Diagramm

Austenitization Temperature: 1080°C, Holding Time: 15 Minutes

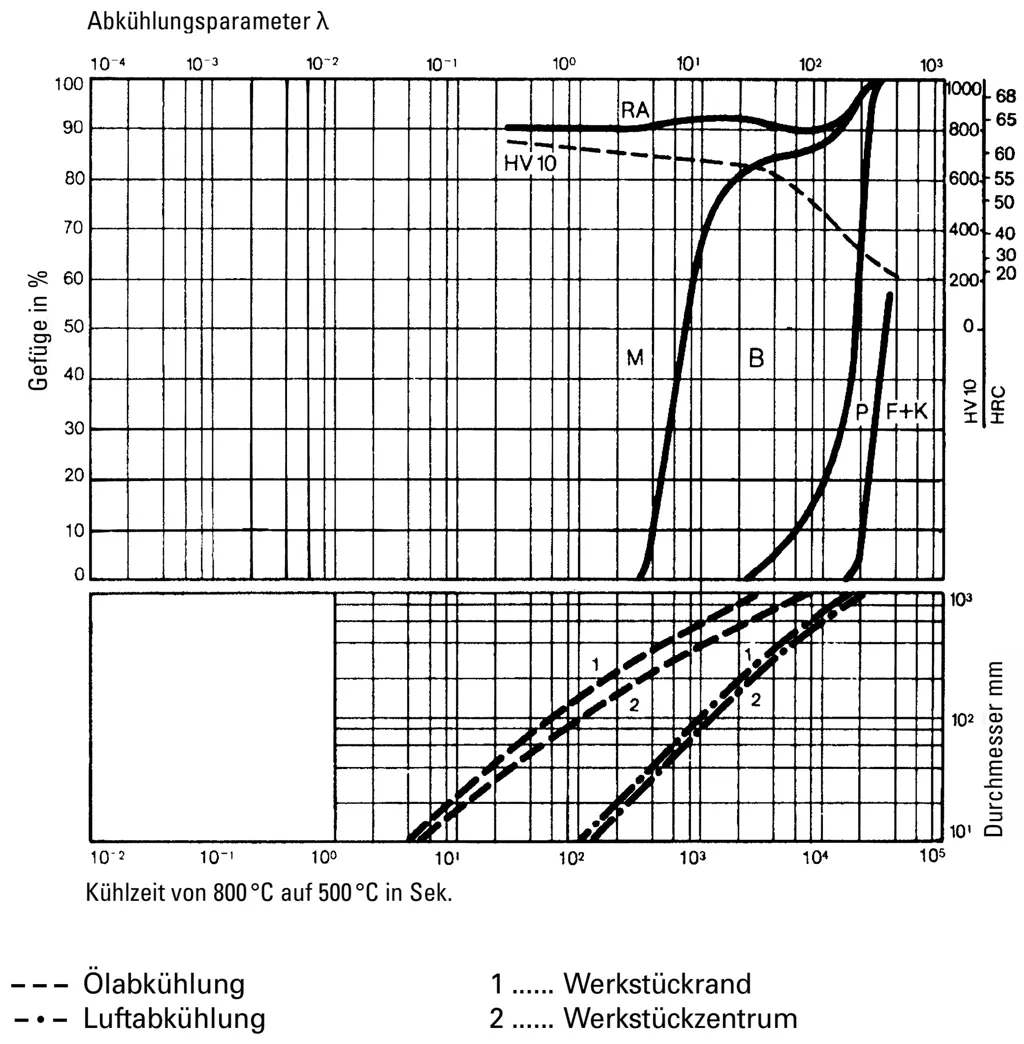

Microstructure Phase Diagram

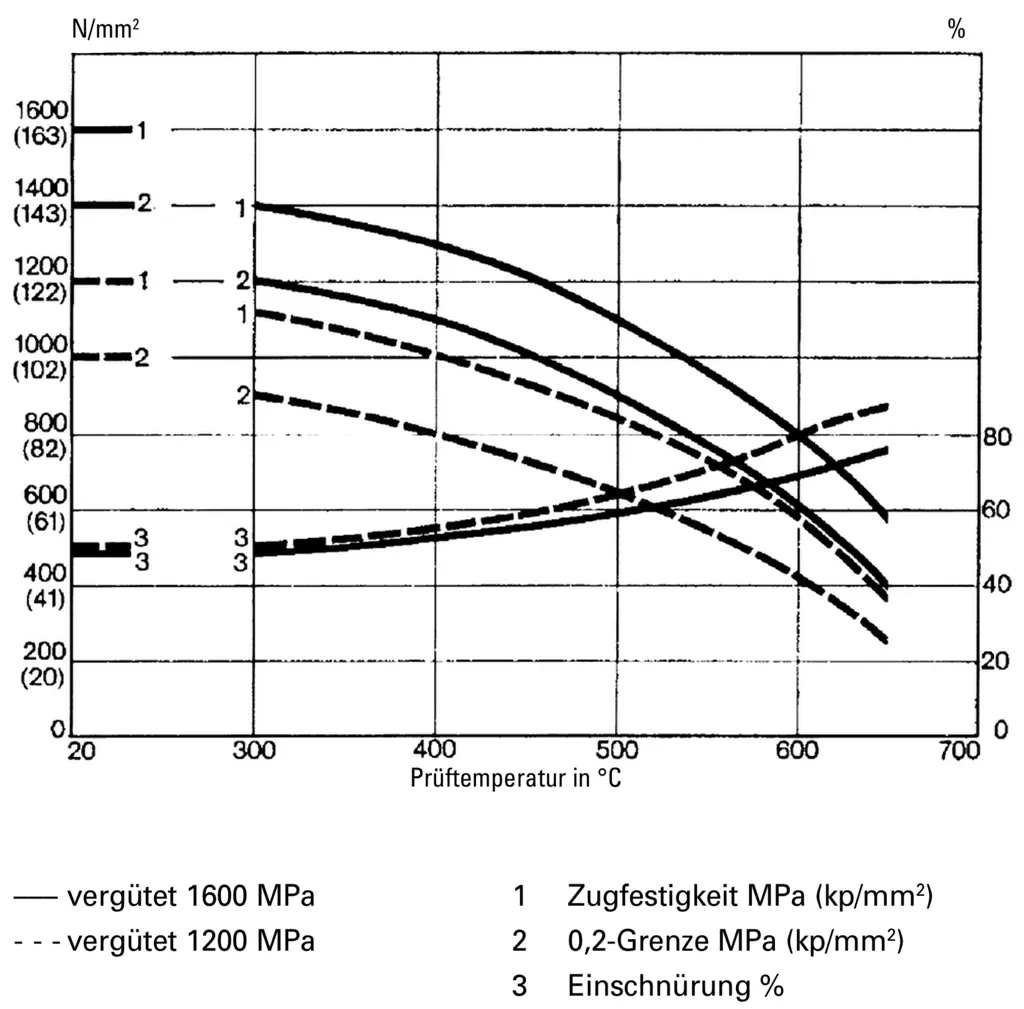

High-Temperature Strength Diagram

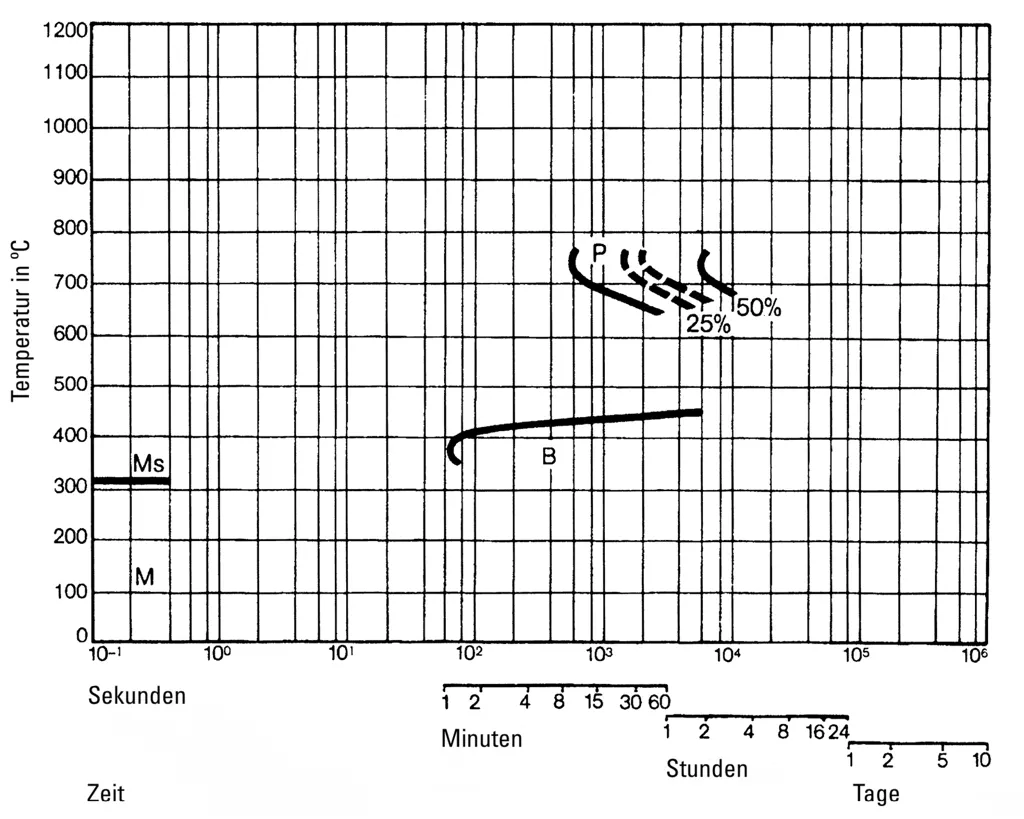

Isothermal Time Temperature Transformation-Diagramm

Austenitization Temperature: 1030°C, Holding Time: 15 Minutes

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.