VarioDuct - hardened adhesive strips

Hardened and ground „adhesive strips“ are often used for both new machines and systems as well as in retrofit applications.

VarioDuct is a standard range of common adhesive strip dimensions, Thickness 4 mm, with freely selectable length and freely selectable chamfers on the longitudinal edges. Your desired length is produced at short notice by cooled CBN cut-off grinding, and the desired chamfers are ground up to 2 x 45° per edge. Chamfers are usually applied when the strips are to be glued into a groove milled into the machine bed.

VarioDuct is available in Standard widths: 20, 25, 30, 35, 40, 45, 50, 55 and 60 mm

Material: 1.2842 / 90 MnCrV 8, through-hardened, 58-62 HRC.

Top side: Fine grinding, Ra = 0.8 μm

Bottom side + Width: Cross grinding, Ra = 6 μm (rough for better adhesion)

Length: freely selectable between 100 and 1,800 mm (widths 20, 35 and 60 mm to 3,200 mm), optionally with face grinding

click here and calculate your individual adhesive strips - VarioDuct

Designations of the optional chamfers on longitudinal edges:

Execution:

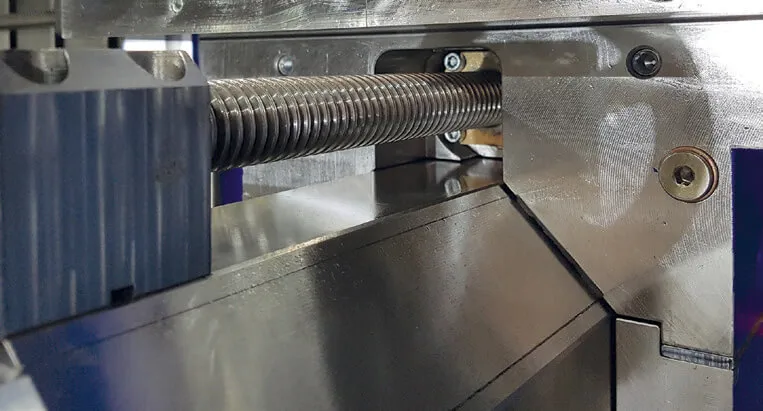

Installation example: Step

Chamfer E and Chamfer G selected, longitudinal edges F and H sharp-edged.

Order example:

VarioDuct, adhesive strip, 40 x 4 x 1,000 mm, Chamfer E = 0.5 mm, Chamfer G = 1 mm, End faces ground at an angle.

Order example:

VarioDuct, adhesive strip, 40 x 4 x 1,000 mm, Chamfer E = 0.5 mm, Chamfer G = 1 mm, End faces ground at an angle.

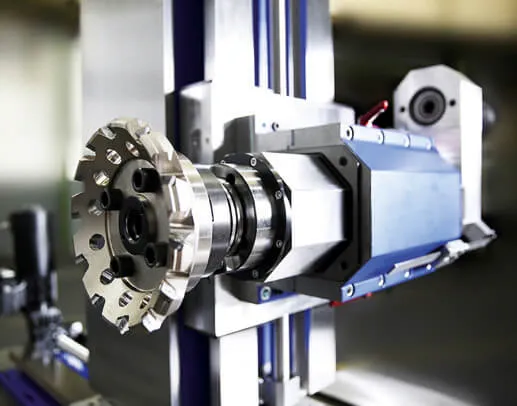

Installation example: Groove with lateral guidance and undercut

Chamfer G and Chamfer H selected and longitudinal edges E and F sharp-edged

Order example:

2 pieces VarioDuct adhesive strip, 40 x 4 x 1,800 mm, Chamfer G = 1 mm, Chamfer H = 1 mm, 1 pieces VarioDuct adhesive strip, 25 x 4 x 1,800 mm, Chamfer G = 1 mm, Chamfer H = 1 mm,

Available for the following grades:

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.