Steel Glossary

1.2363 X 100 CrMoV 5

AISI A2, BS BA2, AFNOR Z 100 CDV 5

| C | Si | Mn | P | S | Cr | Mo | V | |

|---|---|---|---|---|---|---|---|---|

| max. | 1.05 | 0.4 | 0.8 | 0.03 | 0.03 | 5.5 | 1.2 | 0.35 |

| min. | 0.95 | 0.1 | 0.4 | 4.8 | 0.9 | 0.15 |

Cold Work Tool Steel for the production of cutting tools, thread rolling dies, as well as shear blades and hardened guide bars of large cross-sections.

The material 1.2363 fills the gap between 1.2842 and 1.2379. It can be easily machined similar to 1.2842. Grinding of hardened components is also easier compared to 1.2379. 1.2363 can be vacuum hardened very well, similar to 1.2379.

1.2363 should be used when the wear resistance or through-hardening capability of 1.2842 is insufficient for the application task, but 1.2379 is not yet absolutely necessary or too brittle.

1.2363 can be well machined and can be hardened up to 63 HRC. Good wear properties can be achieved through secondary hardening. Larger cross-sections of guide bars can be well through-hardened; thus, 1.2363 is the ideal material for hardened guide bars over 40mm thickness.

You can obtain this material from us as precision flat steel (standard and custom dimensions), VarioPlan, in the form of ready-to-install, hardened guide bars according to your drawings, as well as semi-finished products tailored to your requirements.

As with tool steels in general, there is a risk of cracking during repair welding.

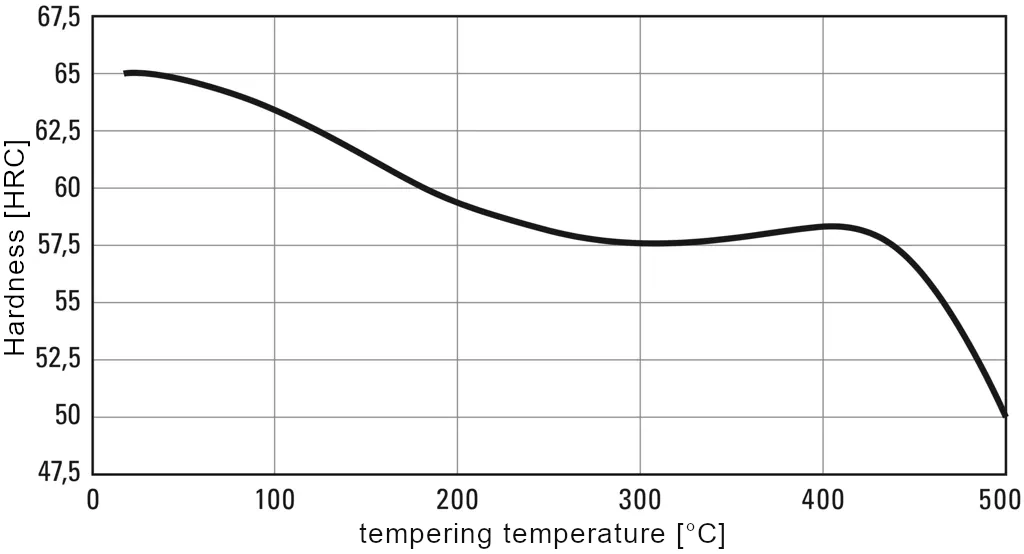

Tempering Diagram

Hardening Temperature: 970°C / Oil, Cross-Sectional Sample: Square 20 mm

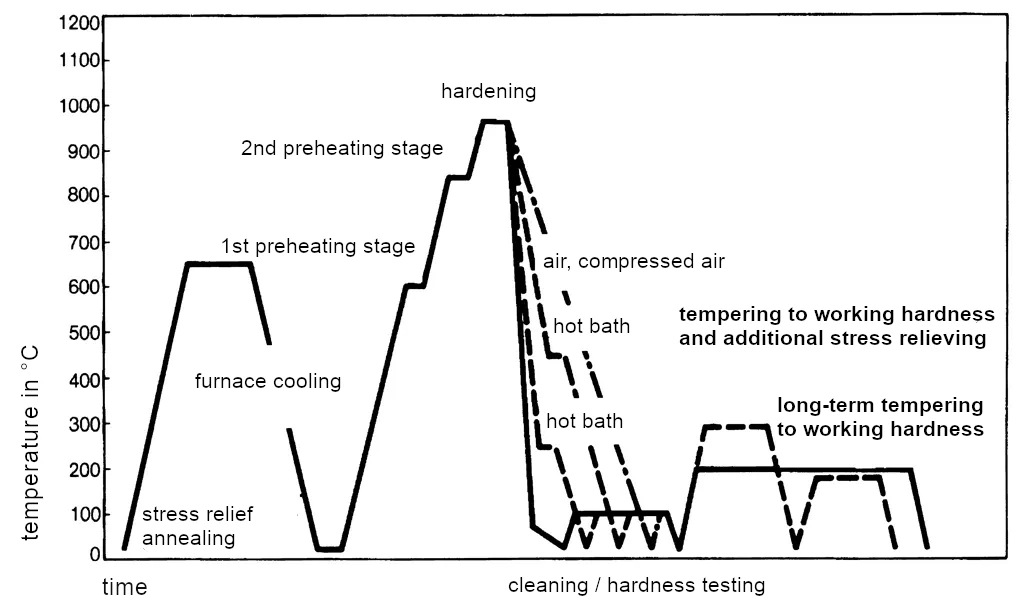

Heat Treatment Schedule

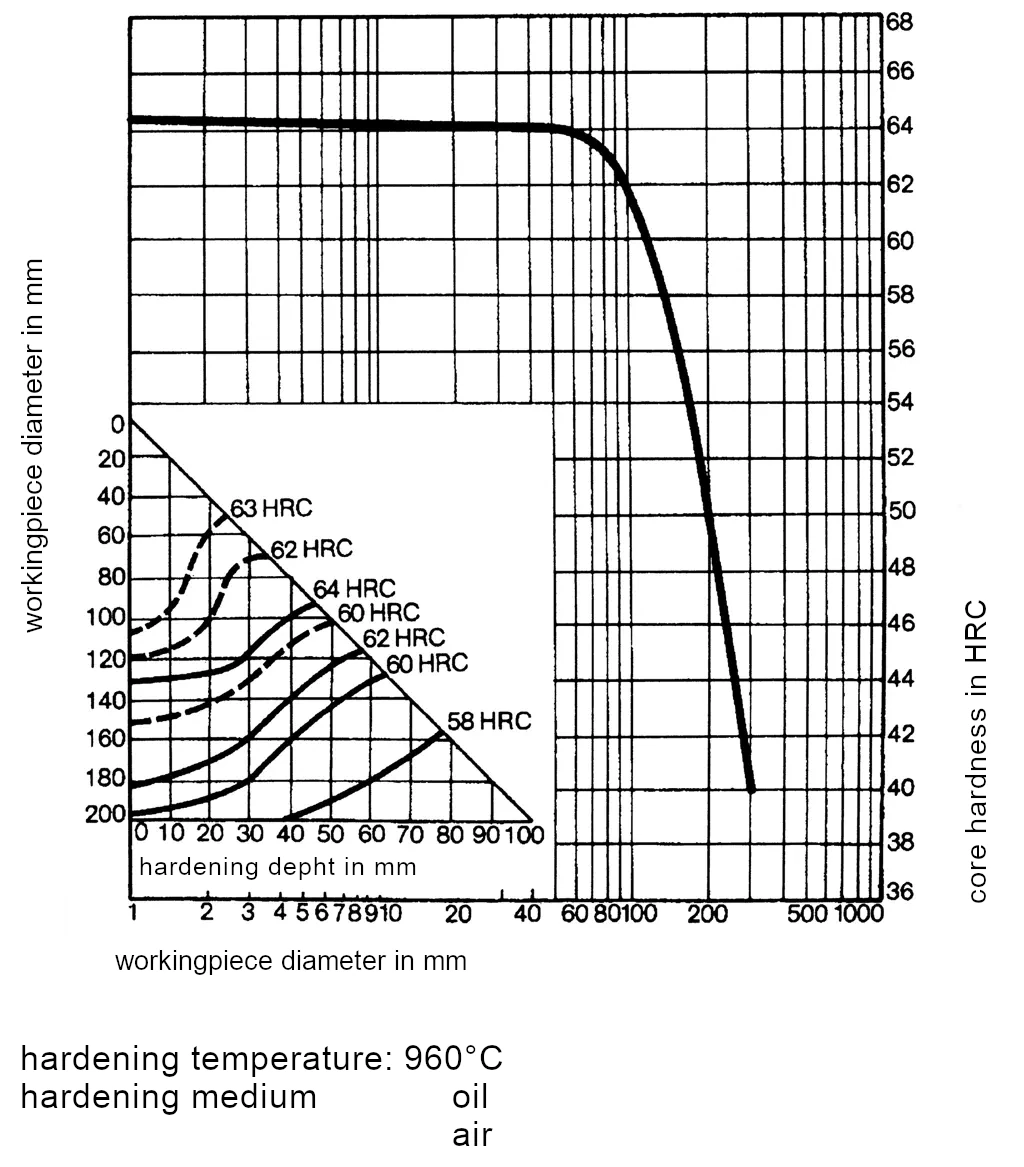

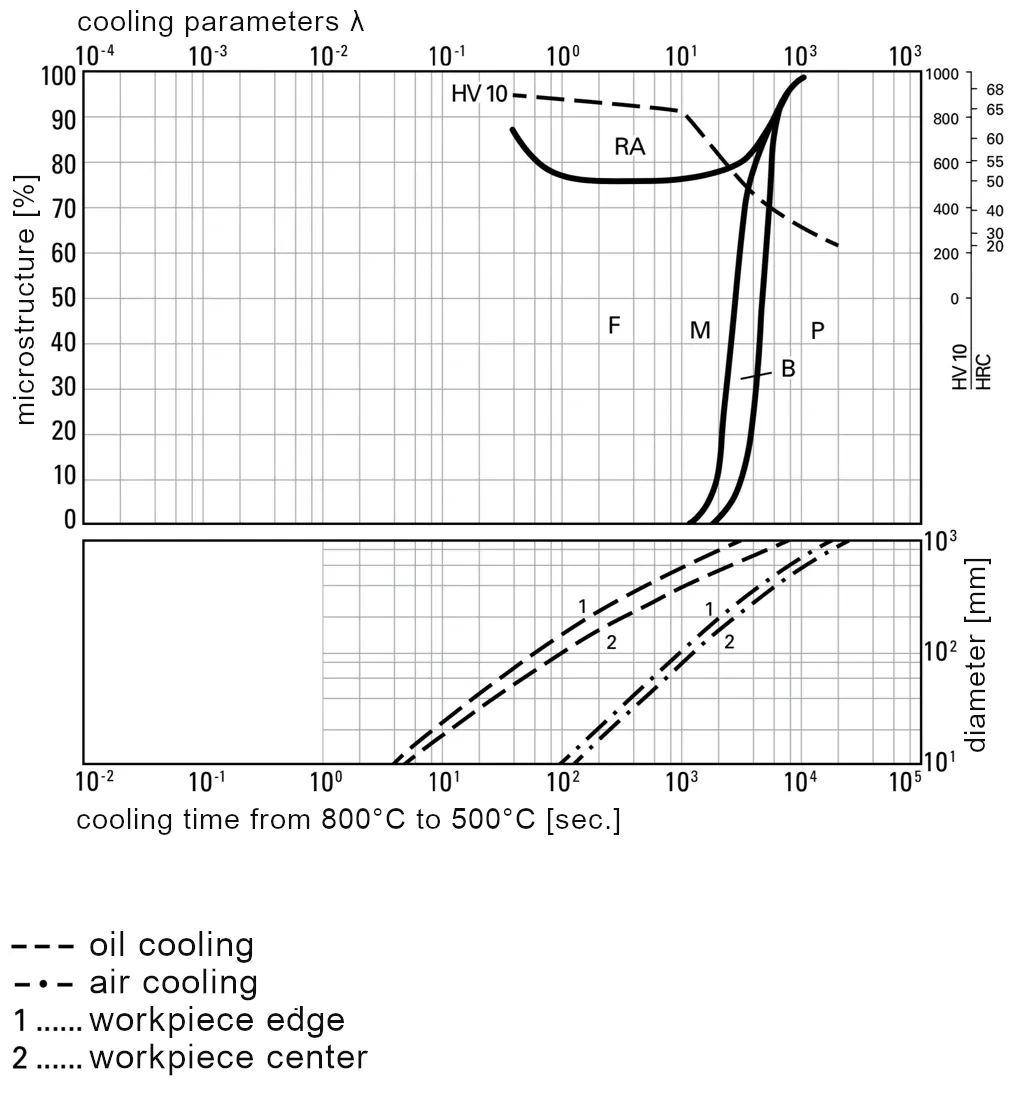

Dependency of Core Hardness and Effective Hardening Depth on Workpiece Diameter

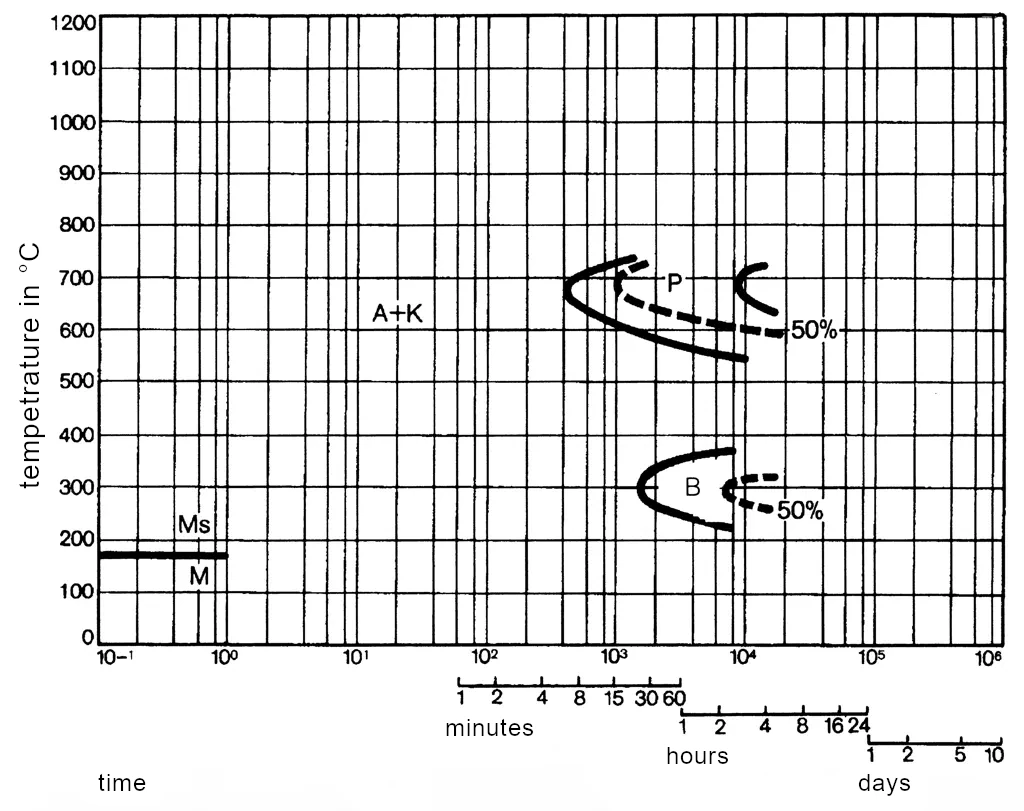

Isothermal Time Temperature Transformation Diagram

Austenitization Temperature: 960°C, Holding Time: 15 Minutes

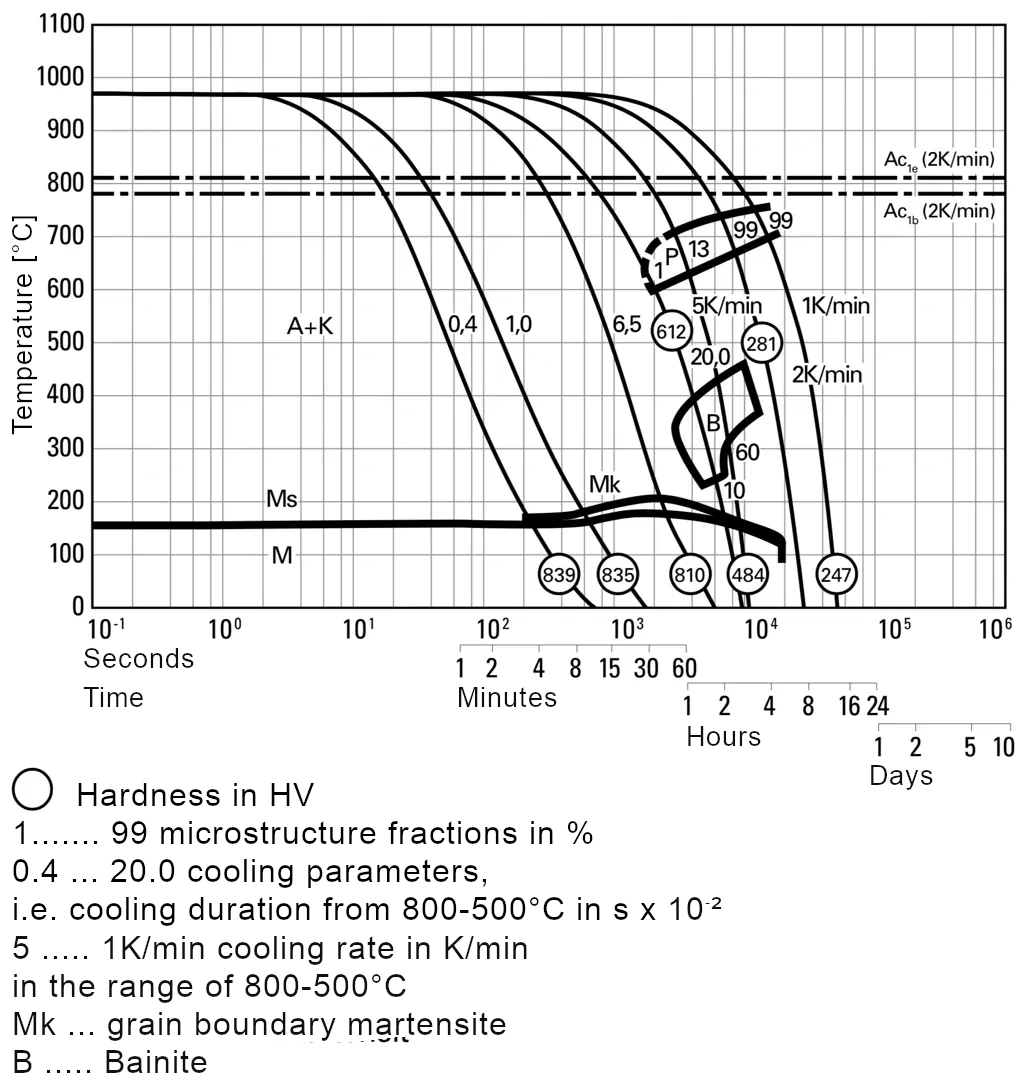

Continuous Cooling Transformation Diagram

Austenitization Temperature: 960°C, Holding Time: 15 Minutes

Microstructure Phase Diagram

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.