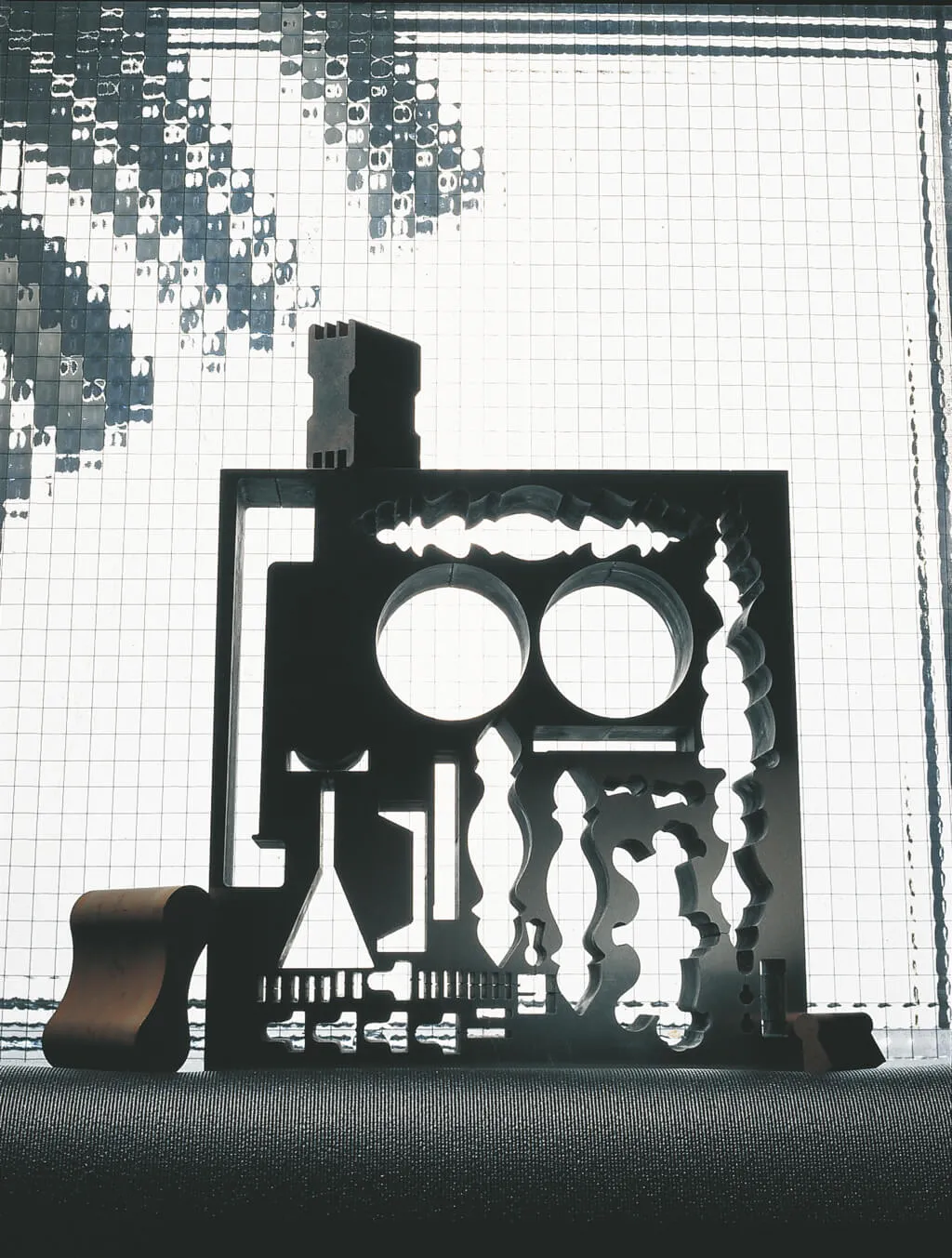

EroBlock - erosion blocks

- optionally with start hole as required

- grain direction perpendicular to the top side

- vacuum hardened or annealed execution

- always available from stock

- corrosion protective packaging

In the manufacturing of die plates and punches in modern toolmaking using wire erosion machines, material selection is of particular significance. Often, cut-offs which have accumulated elsewhere are used for producing punches whose structure (grain direction) is just as unknown as the internal stress situation due to previous machining.

A further problem is the demanding heat treatment which cannot always be ideally performed in-house. The consequences, then, are the reduced working time of the finished tool, frequent reworking and shortened service life until it is scrapped due to a hardness defect. EroBlock erosion blocks plug this flaw in material provision: annealed, vacuum or micro-grain hardened - the blocks are offered in a wide variety of dimensions as standard ground stock.

Start holes are applied as per consultation and specials are possible at short notice. Due to the earmarked semi-finished material selection, it is ensured that the grain always runs in the cutting direction. In combination with modern vacuum hardening techniques in addition to three-fold annealing, the result is an optimum, hardened, semi-finished product low in residual austenite. The service life and production reliability of the finished tool is appreciably increased using EroBlock erosion blocks.

EroBlock erosion blocks can be used for manufacturing the most diverse punch forms. A higher level of utilisation guarantees optimum economy.

Available for the following grades:

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.