Machine components

A high level of materials expertise is one of the keys to optimising your machine components. Often the selection of the right combination of material and heat treatment is decisive for the service life, function and precision of machine components.

Tell us your application conditions, and we will prepare a recommendation for the material and heat treatment concept. The service life of your components is crucial. This is influenced by hardness and toughness, by wear and heat resistance, by tensile and compressive strength, corrosion resistance and polishing properties.

The manufacturing process is the other key to economically priced parts. Define your surface requirements and tolerances to us. We will then prepare a recommendation for the right process whether it's hard machining by milling, profile grinding or high performance milling. At the end will emerge a ready-to-fit precision component, promptly delivered and sometimes cheaper than originally thought.

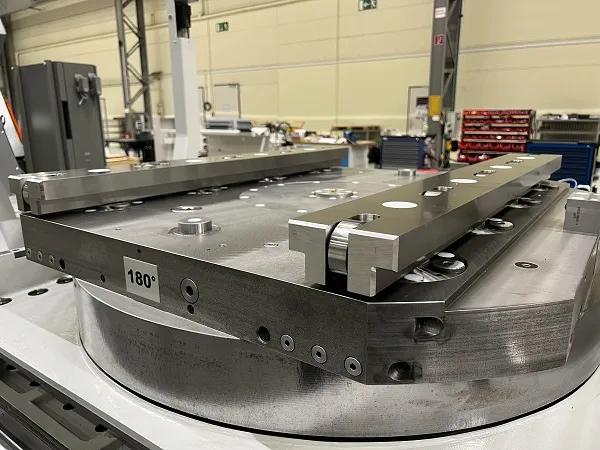

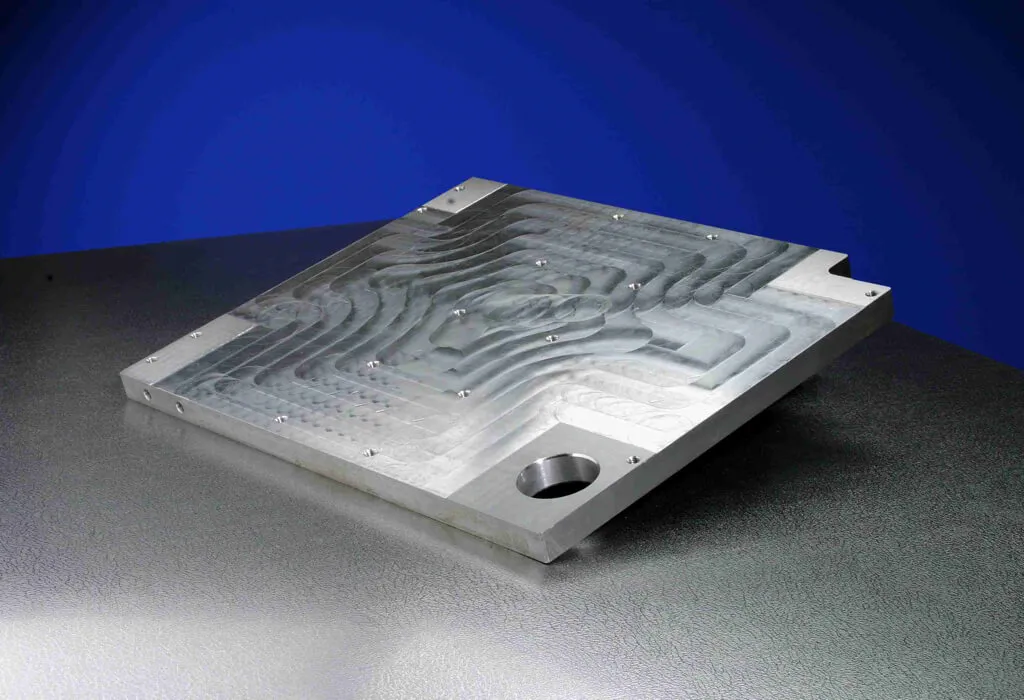

For two-dimensional machine baseplates or fixtures with a precision ground face with fits and threads then we are your partner with the experience. Machine base bodies in long, narrow configurations such as for automation engineering or test jigs are something we have long been familiar with.

Your profile ground parts such as rotary pistons or bending tools up to 2,500 mm in length are in good hands with us.

We manufacture special knives beyond what you can expect from standard solutions from the tough cold work steels Daido DCMX and Daido DRM3, the exceptionally tough high-speed hot work steel Daido DRM1 or the heat-resistant Toolox 44. Our products prove their service life advantage every day in production and recycling, in hot and cold cutting.

There are many remits. Refer your next design to us. You can find our maximum dimensions under subcontracting.

Contact: rps@stahlnetz.de

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.