Steel Glossary

1.2379 D 2/BD 2

AISI D2, BS BD2, AFNOR Z160CDV12

| C | Si | Mn | P | S | Cr | Mo | V | |

|---|---|---|---|---|---|---|---|---|

| max. | 1.60 | 0.6 | 0.6 | 0.03 | 0.03 | 13.0 | 1.0 | 1.0 |

| min. | 1.45 | 0.1 | 0.2 | 11.0 | 0.7 | 0.7 |

Cold work tool steel used for manufacturing dimensionally stable high-performance cutting tools with good toughness and excellent wear resistance.

1.2379 is a ledeburitic 12% chromium steel that requires a high-quality heat treatment. The hardening temperature is above 1,000°C.

In its hardened state, this material is machinable with suitable tools due to its wear resistance.

You can obtain this material from us as precision flat steel (standard and custom dimensions), EcoPlan, annealed or hardened EroBlock, VarioPlan, VarioRond, and as raw material cut-to-size.

We also offer 1.2379 customized according to your specifications as a machine component or as pre-heat-treated guide bars and machine knives.

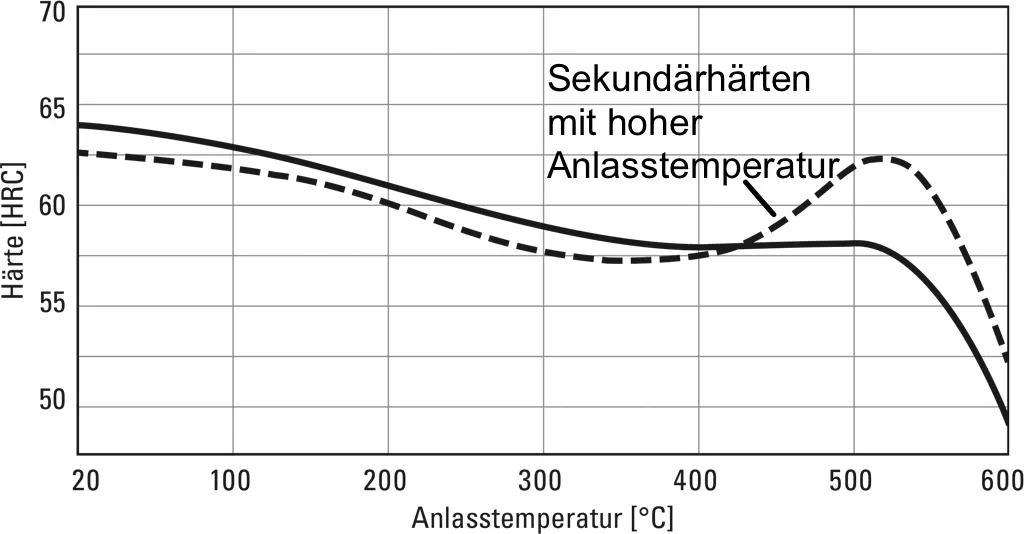

Tempering Diagramm

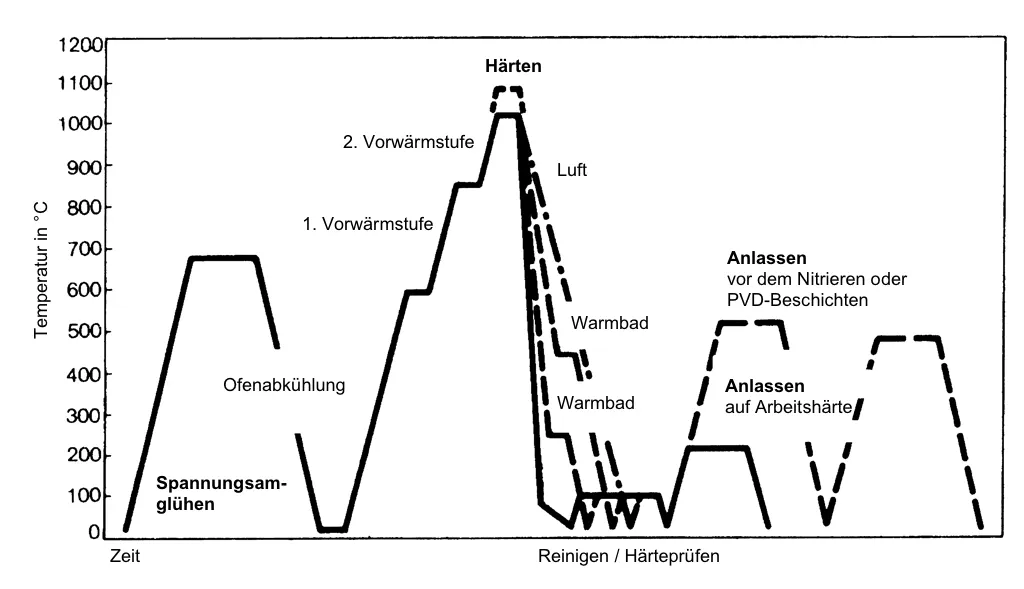

Heat Treatment Schedule

Austenitization Temperature: 1,020°C, Holding Time: 30 Minutes

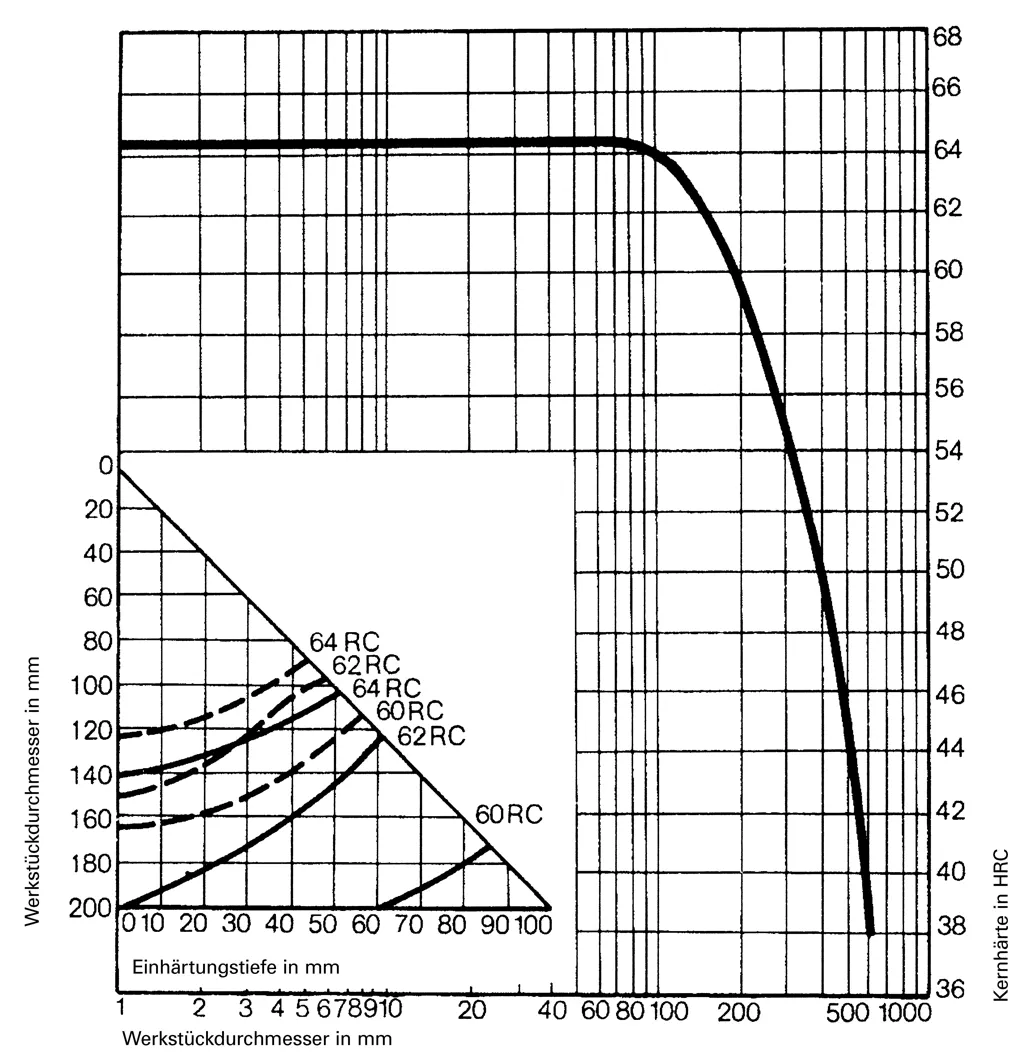

Dependency of Core Hardness and Effective Hardening Depth on Workpiece Diameter.

- Hardening Temperature: 1,030 °C

- Quenching Medium:

- Oil

- - - Air

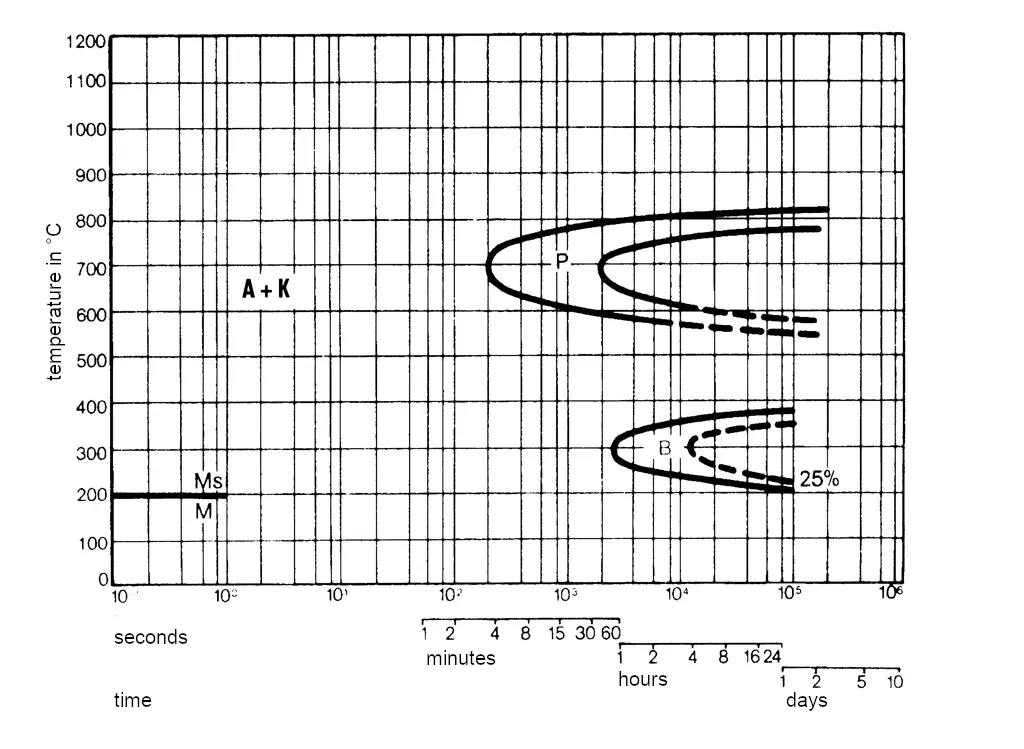

Isothermal Time Temperature Transformation Diagram

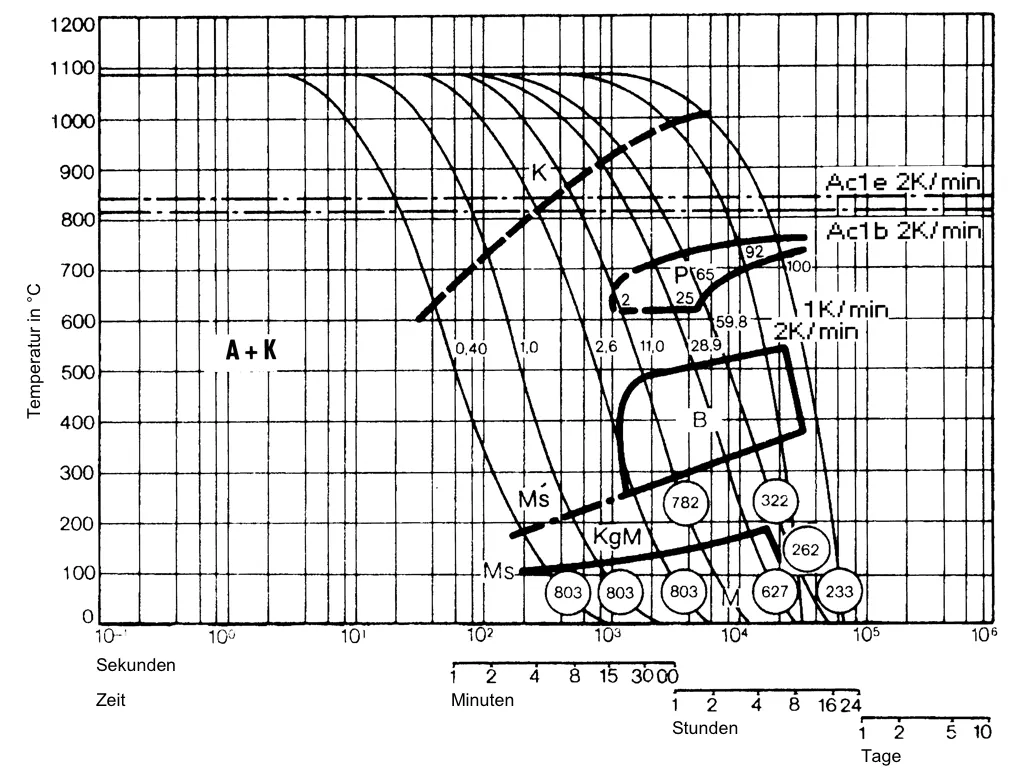

Continuous Cooling Transformation Diagram

Austenitization Temperature: 1080°C, Holding Time: 30 Minutes

- ○ Hardness in HV

- 2 . . . 100 Volume Fraction in %

- 0.40 . . . 59.8 Cooling Parameter, i.e., Cooling Time from 800–500°C in s x 10-2

- 2 . . . 1K/min Cooling Rate in K/min in the Range of 800–500°C

- Ms'-Ms ............. Range of Grain Boundary Martensite Formation

- KgM .................. Grain Boundary Martensite

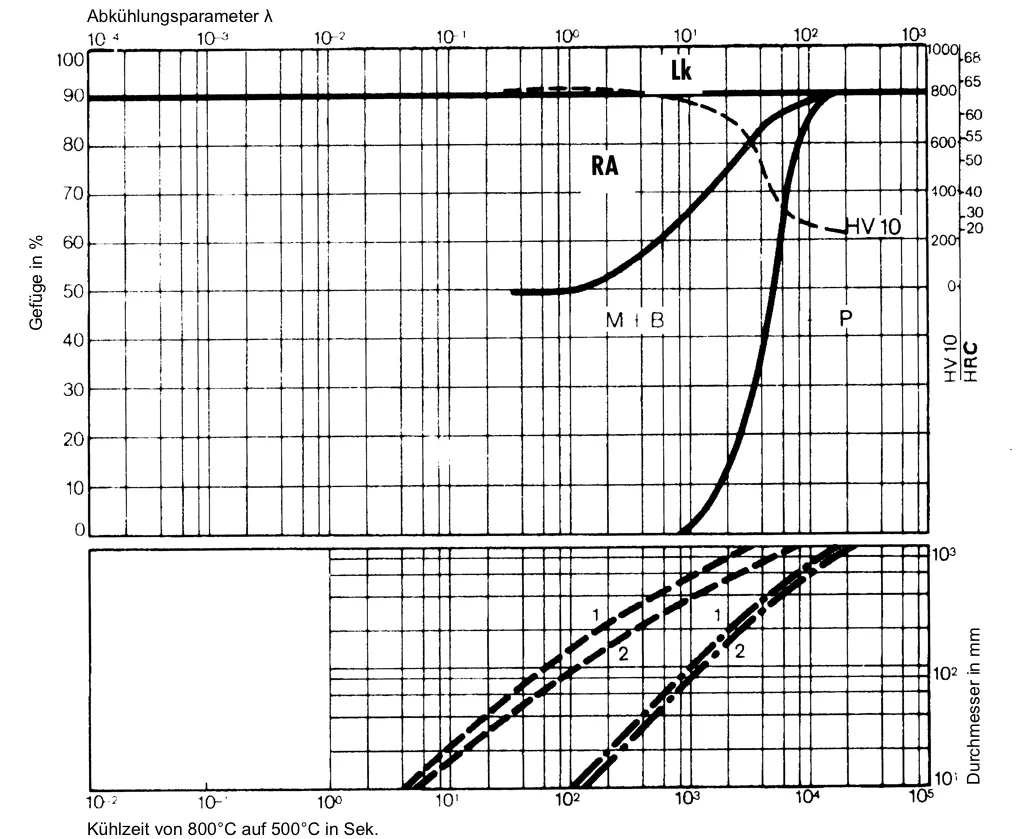

Microstructure Phase Diagram

- Lk ........... Ledeburite Carbide

- RA ........... Retained Austenite

- B ............. Bainite

- P ............. Pearlite

- K ............. Carbide

- - - - Oil Quenching

- - • - Air Cooling

- 1 ............. Workpiece Edge

- 2 ............. Workpiece Center

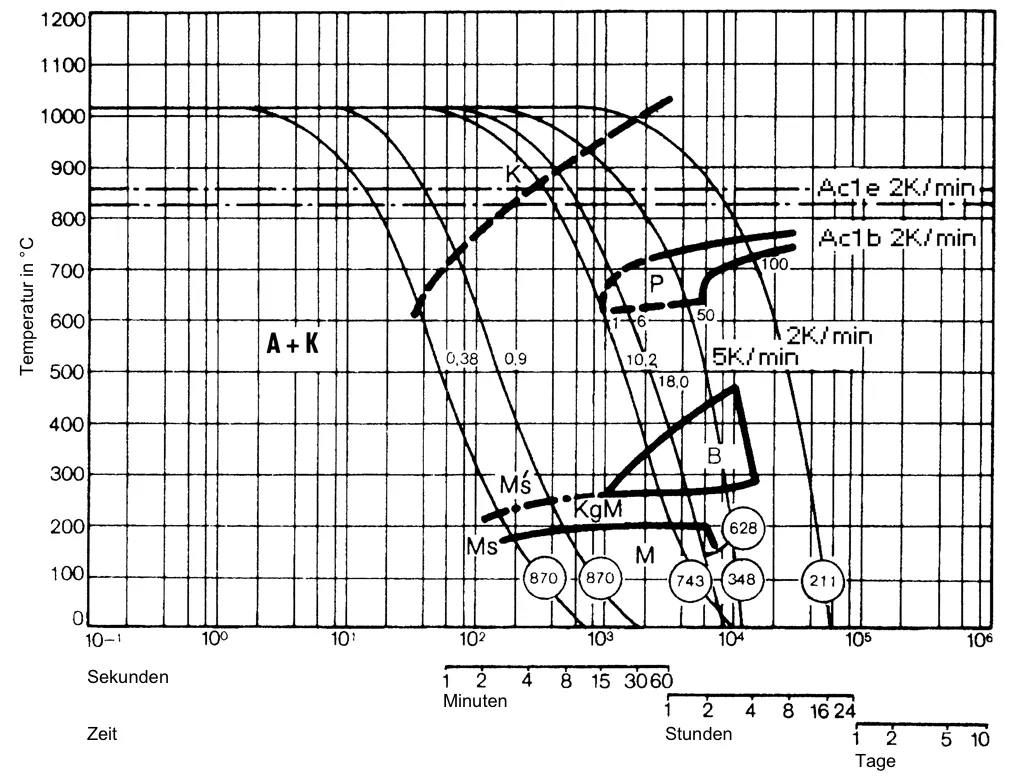

Continuous Cooling Transformation Diagram

Austenitization Temperature: 1020°C, Holding Time: 30 Minutes

- ○ Hardness in HV

- 1 . . . 100 Volume Fraction in %

- 0.38 . . . 18 Cooling Parameter, i.e., Cooling Time from 800°C to 500°C in s x 10-2

- 5 . . . 2K/min Cooling Rate in K/min in the Range of 800°C to °C

- Ms'-Ms ............. Range of Grain Boundary Martensite Formation

- KgM .................. Grain Boundary Martensite

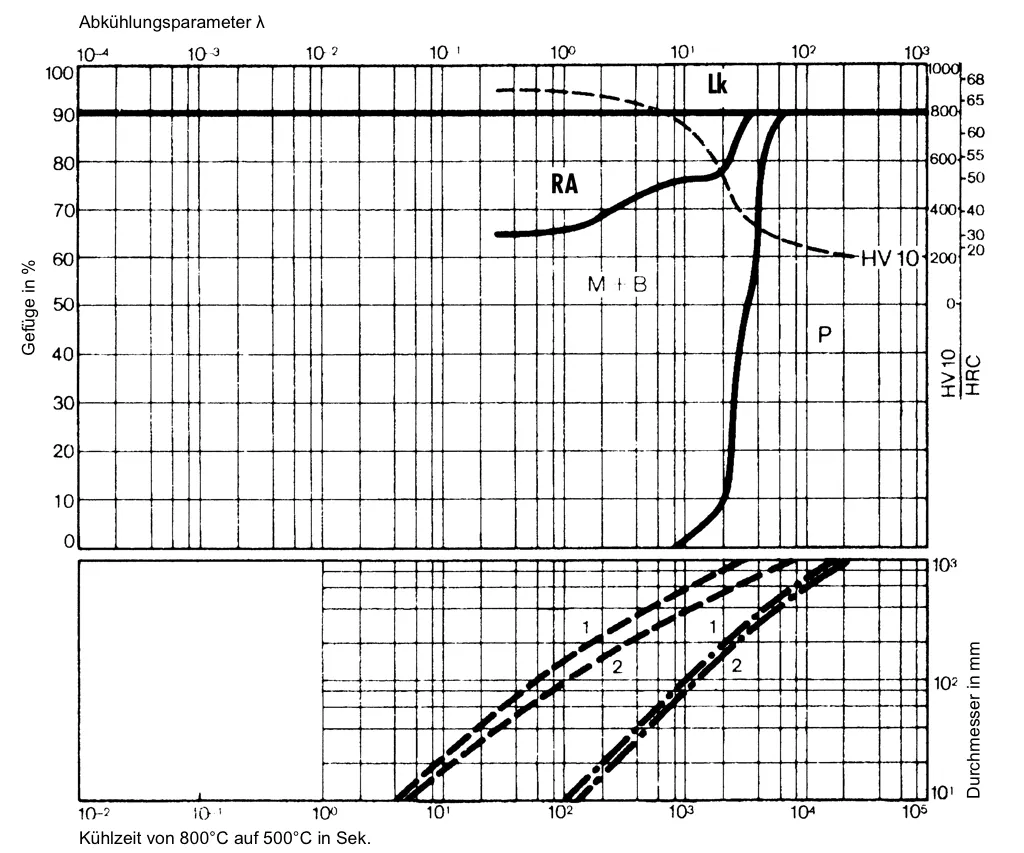

Microstructure Phase Diagram

- Lk ........... Ledeburite Carbide

- RA ........... Retained Austenite

- B ............. Bainite

- P ............. Pearlite

- K ............. Carbide

- - - - Oil Quenching

- - • - Air Cooling

- 1 ............. Workpiece Edge

- 2 ............. Workpiece Center

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.