CNC milling

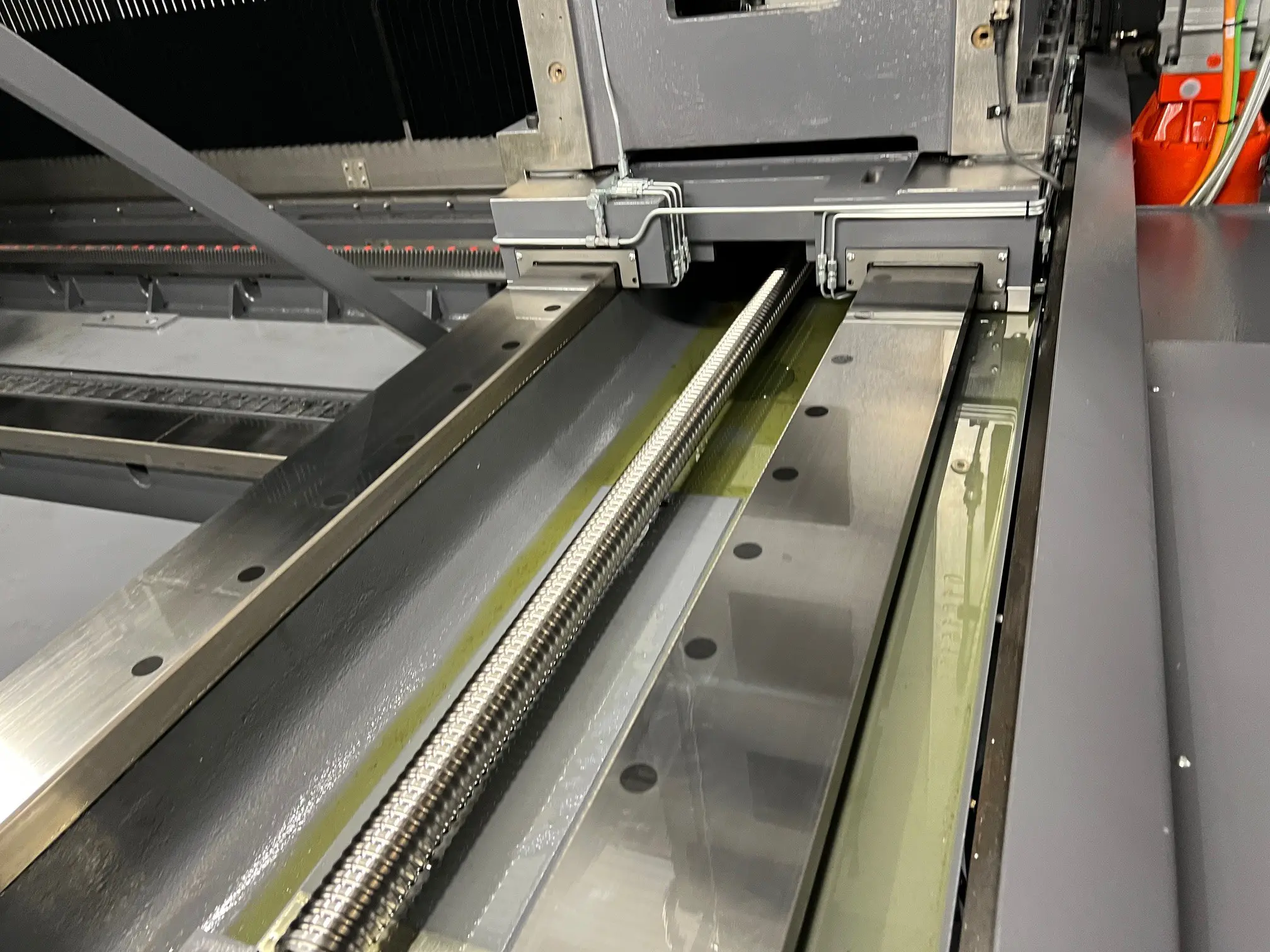

10 CNC machining centers, e.g. AXA VHC 3-6.000, Hedelius BC 100

- Width: 1,000 mm

- Thickness: 700 mm

- Length: 4,500 mm, end machining possible in one setup with +/- 100° swivel head

- Workpiece clamping with magnet or CNC-controlled hydraulic clamping system

- 56 kW / 540 Nm main spindle drive, 144-position tool changer HSK 100

High-performance CNC machining centers, e.g. with Heidenhain TNC 7 controls, and experienced skilled workers, mostly trained in-house, are complemented by powerful CAD/CAM systems (MASTERCAM, Siemens NX CAD/CAM) for transferring your design data into our CNC programs.

Thanks to the optimal interaction of these three components, your workpieces are manufactured quickly, reliably, and precisely. Whether single parts or series, small parts or large components (up to 10 t), we are equipped to meet your requirements.

We manufacture CNC milled parts from low-alloy steels as well as high-alloy, quenched and tempered, or hardened tool steels. The perfect parts for your requirements.

Contact: rps@stahlnetz.de

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.