Steel Glossary

Toolox 44

| C | Si | Mn | P | S | Cr | Mo | V | Ni | |

|---|---|---|---|---|---|---|---|---|---|

| Max. | 0.32 | 1.1 | 0.8 | 0.01 | 0.003 | 1.35 | 0.8 | 0.14 | 1.0 |

| Min. | 0.6 |

Toolox 44 is a hardened and tempered tool steel designed to minimize residual stresses, resulting in excellent

dimensional stability during machining. Despite having a hardness of 45 HRC, Toolox 44 exhibits good

machinability.

This tool steel is specifically intended for plastic molds and is highly suitable for

polishing and texturing.

Other applications include sheet metal forming tools, wear parts, structural

components, and machine spindles.

| Hardness (Guaranteed Value) |

HBW 410 – 475 (equivalent to approximately 41 – 47 HRC) | |

| Charpy Impact Strength (Guaranteed Value) |

Test Temperature 20°C |

Charpy-V Impact Strength Transverse direction ≤ 130mm, minimum 18 J |

| Tensile Strength (Converted Value) |

Tensile Strength approximately 1450 MPa | |

| Ultrasonic Testing (Guaranteed Value) |

According to EN 10160 (plates) or EN 10228-3 (forgings) and additional requirements per SSAB V6. | |

| Etching Properties (Guaranteed Obligation) |

Toolox 44 complies with the requirements of NADCA 207–2006. | |

| Dimensions | Toolox 44 is available in plate thicknesses from 6mm to 130mm. | |

| Delivery Condition | Hardened and tempered at a minimum of 590°C. | |

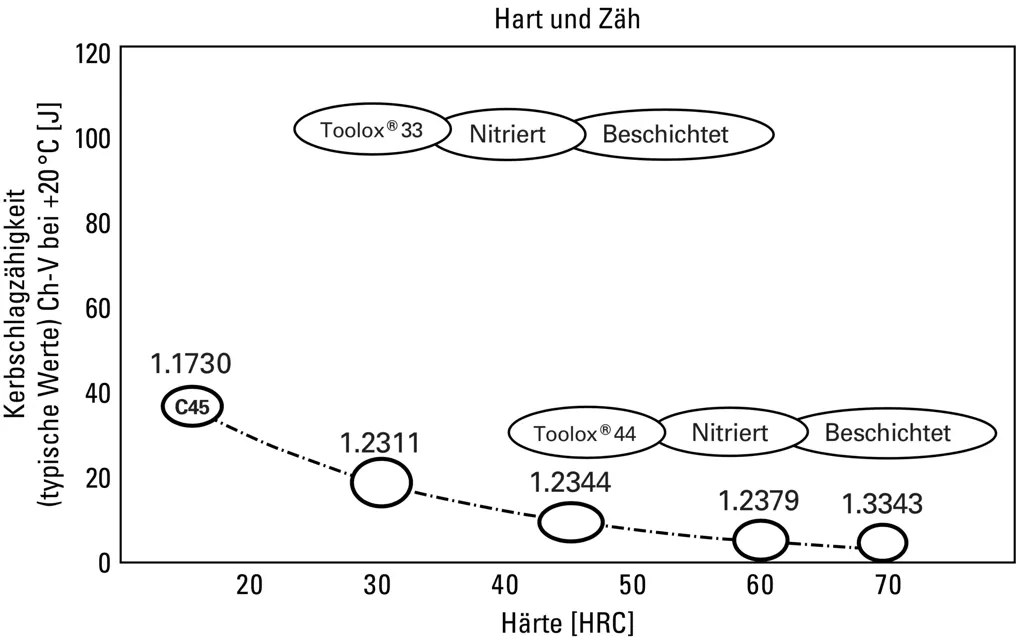

| Heat Treatment | Nitriding or coating is possible at temperatures below 590°C. Toolox 44 is not intended for further heat treatment. If this material undergoes further heat treatment above 590°C after delivery, the properties are no longer guaranteed. | |

| Testing | Testing according to EN 10025 and EN ISO 6506-1. Hardness tested on a milled surface 0.5mm to 2mm below the sheet surface. | |

| Tolerances | Plate: According to SSAB tool steel standard, Forgings: According to DIN 7527 Round Bars: EN 10060 |

|

| Products | Precision flat steel (standard and custom dimensions), EcoPlan, VarioPlan, VarioRond, and raw material blanks. Machine parts and guide bars made to your specifications and drawings. | |

Metallurgical Information

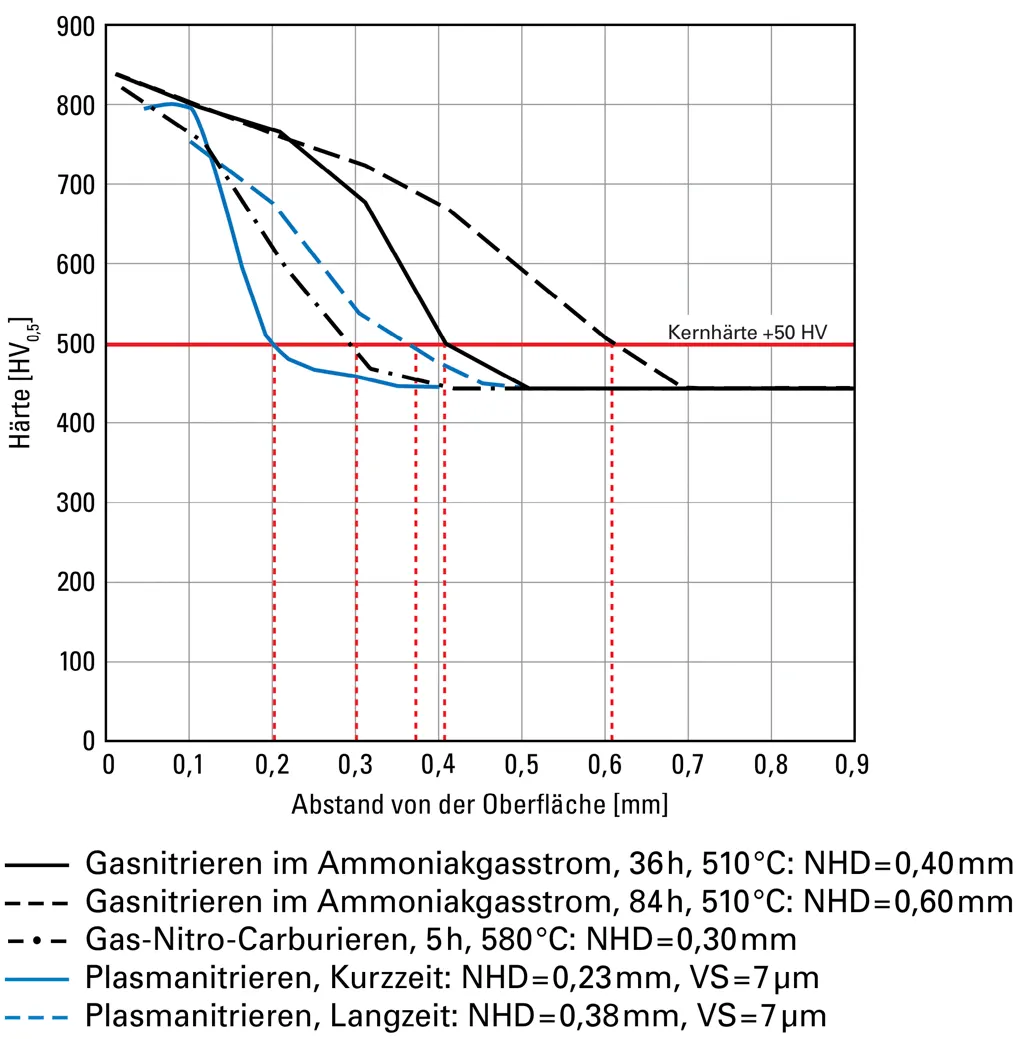

Hardness Profile

Determination of Nitriding Depth NHD according to DIN 50190-3 at core hardness +50 HV

Note: Due to the high core hardness of approximately 450 HV, the effective nitriding depth is easily underestimated compared to lower hardened materials.

Inclusion Content (Typical Values)

| Inclusion Content (equivalent diameter) | 6µm |

| Area Fraction | 0.015% |

| Length-Width Ratio | 1.2 |

Physical Properties (Typical Values)

| Thermal Expansion Coefficient [10-6/K] at +20 – 200°C: |

13.5 | ||||||||

| Thermal Conductivity: |

|

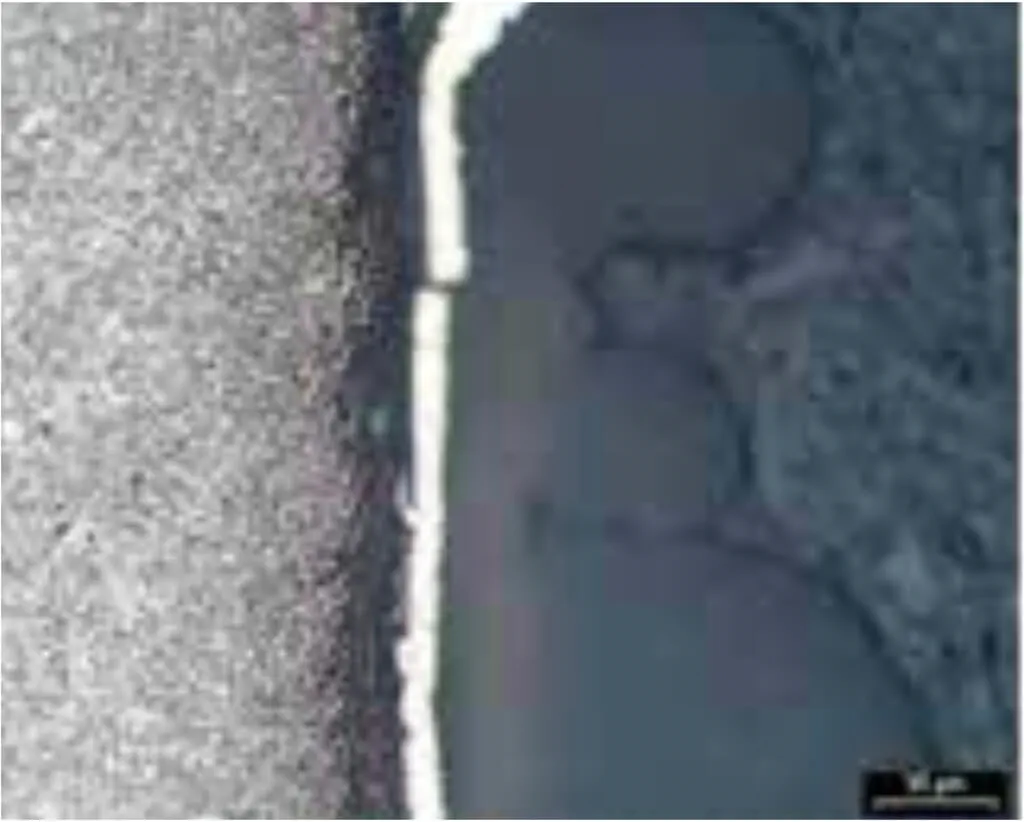

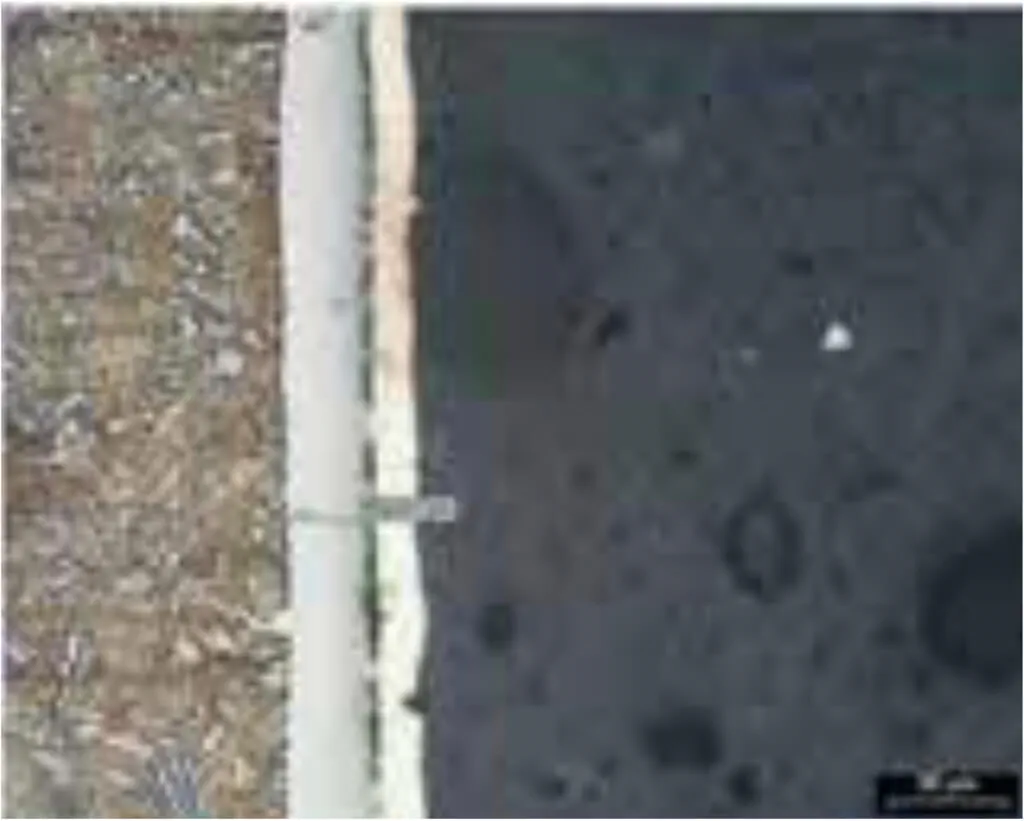

Short-term

Diffusion zone, no bonding layer

Long-term

Diffusion zone, bonding layer 34µm

Surface Technology

Mechanical Properties (typical values*)

| Guaranteed Hardness [HBW] | Hardness typical [HRC]* | Guaranteed Charpy Impact Energy Min [J] | Charpy Impact Energy typical [J]* | Yield Strength typical Rp0,2 [MPa]* | Tensile Strength typical Rm [MPa]* | Elon-gation typical As [%]* | Compression Strength typical MPa* | Compression Strength after 170 hrs holding time typical MPa* | Thickness [mm] | |

|---|---|---|---|---|---|---|---|---|---|---|

| -40°C | 14 | 6 - 130 | ||||||||

| -20°C | 19 | |||||||||

| +20°C | 410 - 475 | 45 | 18 | 30 | 1,300 | 1,450 | 13 | 1,250 | ||

| +200°C | 60 | 1,200 | 1,380 | 10 | 1,120 | |||||

| +300°C | 80 | 1,120 | ||||||||

| +400°C | 80 | 1,060 | 1,060 | |||||||

| +500°C | 930 | 910 |

Toolox is tested for hardness and Charpy impact energy at room temperature.

All other values provided are from additional tests and are for informational purposes only; they are not guaranteed.

* Guideline values for informational purposes only.

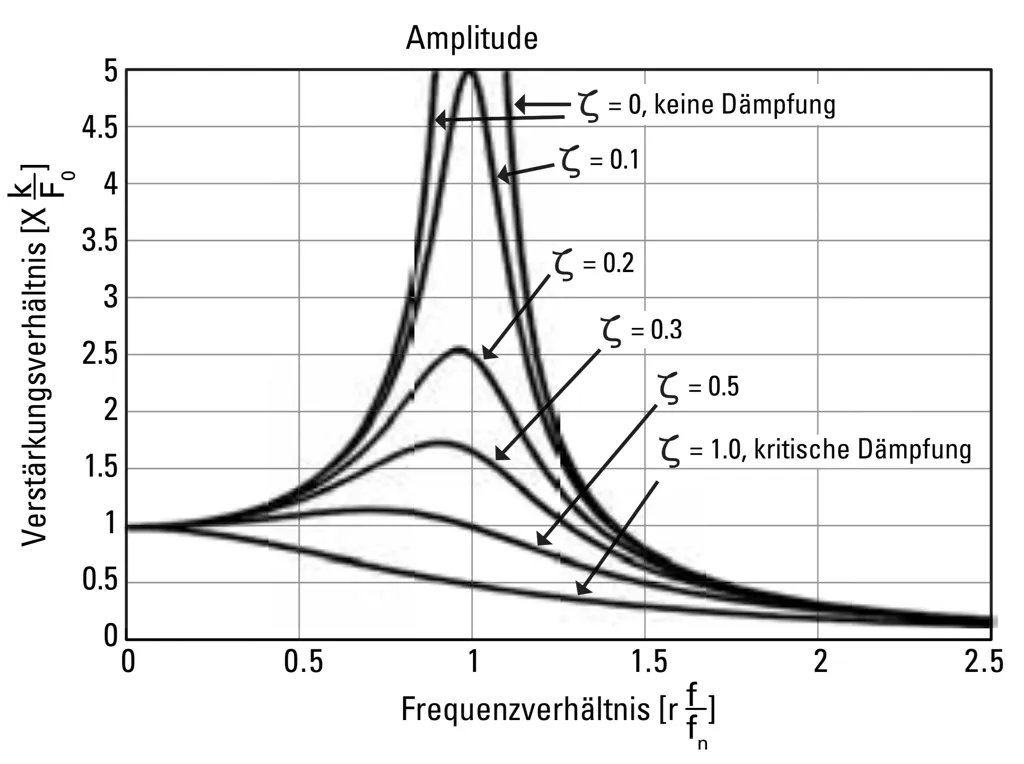

Damping Properties

Toolox 44 has been successfully used in Sweden for high-quality cutting tools such as WP drills, milling cutters, and parting tools. It has demonstrated smooth operation and long tool life, especially when compared to conventional materials. Several scientific studies, including those conducted at the Royal Institute of Technology in Stockholm and by Dr. Svenningsson, attribute these benefits to the excellent damping properties of the material. As a result, the critical depth of cut for Toolox milling cutters is larger than that of conventional tools, enabling the use of slimmer and more extended tools.

These properties make Toolox 44 round material a suitable choice for shafts, spindles, and other machine components where external excitation affects the process and vibrations need to be reduced.

The faster decay of amplitudes due to higher damping significantly improves the fatigue strength of the component and reduces material fatigue.

Over a wide frequency range from 65Hz to 4,000Hz, the damping is very effective, and it increases with the excitation frequency. The damping factor ranges from 1.2% at 120Hz to 2.2% at 4,000Hz, which is considerably higher than that of other steels, even approaching the level of cast iron. While the research is still ongoing, it explains and confirms the observed benefits in operation quite well. Feel free to contact us, and we will be happy to assist you in optimizing your components.

Amplitudes at Different Relative Damping Ratios ζ

| Material | Relative Damping ζ % |

|---|---|

| Gray Cast Iron (GG) | ≈ 2.1 - 2.3 |

| Toolox 44 | 1.9 |

| Toolox 33 | 1.0 |

| S355 (St52) | 0.8 |

| High-Strength Steels (quenched and tempered) | ≈ 0.1 - 0.3 |

Ultrasonic Testing

Each sheet is meticulously inspected, and 3.1 certificates are available. Internal standards often impose stricter requirements than industry standards.

Surface Inspection1)

| According to EN 10 160 | Distance between parallel testing lines [mm] | Minimum detectable defect area [mm²] | Maximum allowable defect area [mm²] | Maximum number of local defects [number/m²] | Corresponding Steel-Delivery Conditions |

|---|---|---|---|---|---|

| - | 100 | 1,000 | 10,000 | 1 | SEL 072 Class 5 |

| S0 | 100 | 1,000 | 5,000 | 20 | - |

| S1 | 100 | 100 | 1,000 | 15 | SEL 072 Class 3 |

| S2 | 50 | 50 | 100 | 10 | SEL 072 Class 2 |

| S3 | 50 | 20 | 50 | 10 | SEL 072 Class 1 |

Edge Zone Inspection2)

| According to EN 10 160 | Edge Zone Width2) [mm] | Minimum detectable defect length [mm] | Maximum allowable defect length [mm] | Maximum allowable defect area [mm²] | Maximum number of defects per meter length | Corresponding Steel-Delivery Conditions |

|---|---|---|---|---|---|---|

| E0 | 50 - 100 | 50 | 100 | 2,000 | 6 | - |

| E1 | 50 - 100 | 25 | 50 | 1,000 | 5 | SEL 072 Class 3 |

| E2 | 50 - 100 | 20 | 40 | 500 | 4 | SEL 072 Class 2 |

| E3 | 50 - 100 | 15 | 30 | 100 | 3 | SEL 072 Class 1 |

| E4 | 50 - 100 | 10 | 20 | 50 | 2 | - |

1) Testing can be ordered and conducted as complete testing, for example, E1S1 or E2S2 , or as edge zone or surface testing only, for example, E1 or S1.

2) The width of the edge zone in edge zone inspection varies depending on the sheet thickness.

The thickness tolerances of the sheets according to AccuRollTech™ are tighter than DIN EN 10 029.

| Nominal Thickness [mm] | Toolox Tolerance Class C [mm] | Maximum Thickness Difference in Sheet [mm] | |||

|---|---|---|---|---|---|

| min | max | ||||

| - | 4.9 | -0.0 | +0.7 | 0.5 | |

| 5.0 | - | 7.9 | -0.0 | +0.8 | 0.6 |

| 8.0 | - | 14.9 | -0.0 | +1.0 | 0.7 |

| 15.0 | - | 24.9 | -0.0 | +1.2 | 0.8 |

| 25.0 | - | 39.9 | -0.0 | +1.5 | 1.0 |

| 40.0 | - | 79.9 | -0.0 | +2.4 | 1.1 |

| 80 | - | -0.0 | +3.2 | 1.2 | |

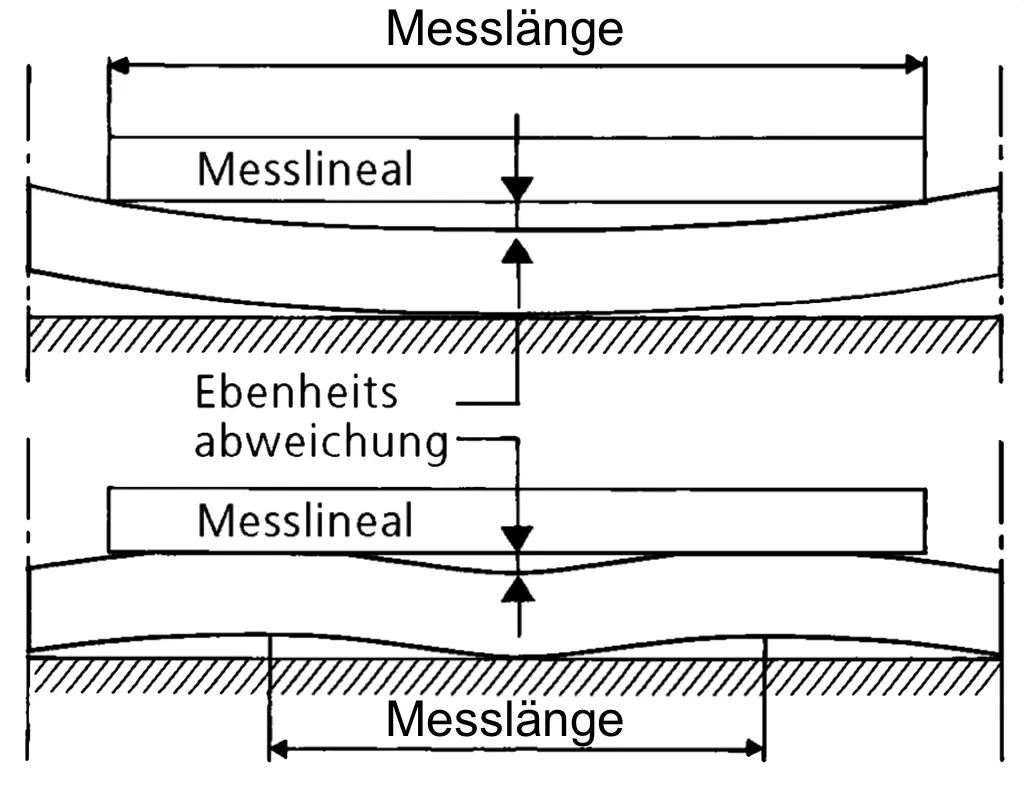

Toolox sheets exhibit remarkable flatness.

| 5.0-7.9 | 8.0-14.9 | 15.0-24.9 | 25.0-99.9 | 100.0-155.0 | ||

|---|---|---|---|---|---|---|

| Toolox 44 | Quarto-Sheet Class S Measuring Length 1,000mm |

4mm | 3mm | 3mm | 3mm | 4mm |

| Quarto-Sheet Class S Measuring Length 2,000mm |

8mm | 6mm | 6mm | 6mm | 8mm | |

Toolox sheets come with a standard corrosion protection coating and individual sheet marking.

Machining of Toolox

Today, all major tool manufacturers are prepared for machining Toolox. It is advisable to seek advice on suitable tools and cutting values. These recommendations should be followed according to textbook principles to achieve optimal results and productive performance. It is essential to avoid reducing the feed rate out of misguided caution. Proper chip formation leads to success, and Toolox rewards you with long tool life and faster machining.

Drilling

Drilling with HSS tools is suitable for less stable machines and low quantities of workpieces. HSS-Co tools with the cutting values provided below have proven to be effective. Pay attention to continuous mechanical feed and sharp tools. A pointed cross-cutting edge would be advantageous to ensure optimal chip formation.

| Toolox 44 | |

|---|---|

| Cutting Speed: v [m/min] | ∼ 7 |

| Diameter [mm] | Feed: f [mm/U] / Speed [1/min] |

| 5 | 0.05/445 |

| 10 | 0.09/220 |

| 15 | 0.15/150 |

| 20 | 0.20/110 |

| 25 | 0.25/90 |

| 30 | 0.30/75 |

| *35 | 0.35/63 |

| *40 | 0.40/55 |

Drilling with solid carbide tools is productive and efficient. It is recommended to use internal coolant supply with a higher concentration. Make sure to drill with continuous feed (not less than the recommendation of the tool manufacturer).

| Toolox 44 | ||

|---|---|---|

| cutting speed: v [m/min] | 40-65 | |

| Diameter [mm] | Feed [mm/U] | |

| min.-max. | Starting Value | |

| 3.0 – 5.0 | 0.06 – 0.11 | 0.07 |

| 5.01 – 10.0 | 0.08 – 0.13 | 0.10 |

| 10.01 – 15.0 | 0.12 – 0.18 | 0.15 |

| 15.01 – 20.0 | 0.16 – 0.20 | 0.18 |

Carbide indexable inserts or brazed cutters are used for medium diameters. Please refer to the table for cutting values.

| Toolox 44 | ||

|---|---|---|

| cutting speed: v [m/min] | 40-60 | |

| Diameter [mm] | Feed [mm/U] | |

| min.-max. | Starting Value | |

| 7.5 – 12.0 | 0.08–0.14 | 0.11 |

| 12.01 – 20.0 | 0.12–0.20 | 0.15 |

| 20.01 – 25.0 | 0.14–0.22 | 0.17 |

| 25.01 – 30.0 | 0.16–0.25 | 0.19 |

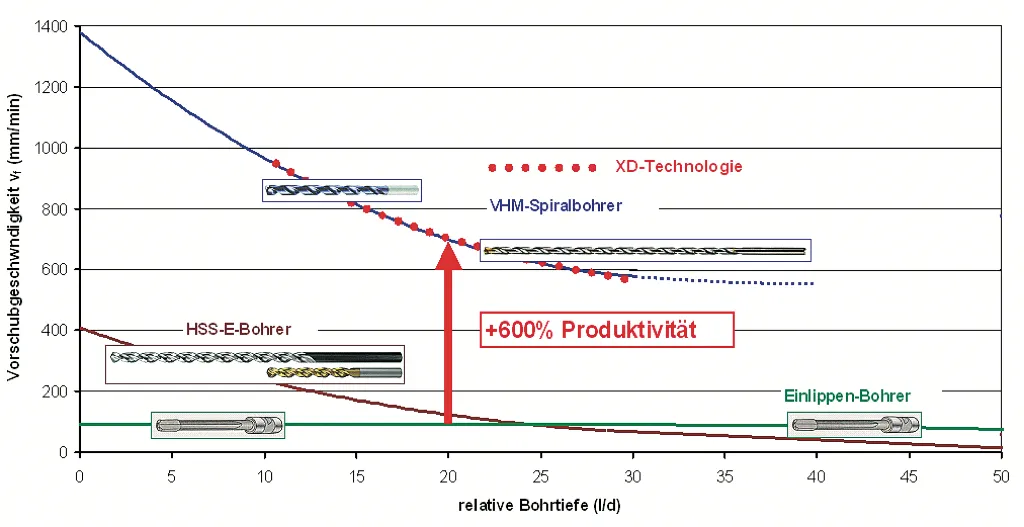

Deep holes up to over 50 x D can also be produced very productively on machining centers with internal coolant supply (IKZ) using VHM drills with special geometry. Typical cutting values are shown in the table below.

| Material | Hardness | Diameter | Depth | Relative Depth | Cutting Data | Coolant | ||

|---|---|---|---|---|---|---|---|---|

| d [mm] | l [mm] | l/d | vc [m/min] | f [mm] | vf [mm/min] | Emulsion | ||

| Toolox 44 | 45 HRc | 5 | 100 | 20 | 36 | 0.15 | 344 | IK, p=20bar |

Deep hole drilling in Toolox presents a special challenge, which the renowned manufacturer Botek masters and solves economically with a special cutting edge geometry. The single-lip solid drilling tools type 110 with special geometry for diameters up to 12.0mm and the single-lip deep hole drilling tools type 01 with interchangeable cutting inserts and guide pads in special design for diameters from 12.0mm have proven to be excellent solutions.

For further information, please contact Botek and refer to us.

| Drilling Ø | 3 | 4 | 5 | 6 | 7 | 8 | 9-10 | 11-12 | >12 |

|---|---|---|---|---|---|---|---|---|---|

| Cutting Speed [m/min] | 50 | 50 | 50 | 50 | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 |

| Feed Rate [mm/U] | 0.005 | 0.01 | 0.012 | 0.015 | 0.015 | 0.0175 | 0.02 | 0.03 | 0.07 |

| Coolant Pressure [bar] | 100 | 100 | 100 | 90 | 90 | 80 | 70 | 60 | 40 |

| Centering Distance [mm] | 40 | 40 | 50 | 50 | 60 | 60 | 70 | 70 | 70 |

| Centering Feed [mm/U] | 0.0025 | 0.005 | 0.006 | 0.0075 | 0.0075 | 0.009 | 0.01 | 0.015 | 0.035 |

Achievable tool life with oil: approx. 2 - 3 meters under optimal process conditions

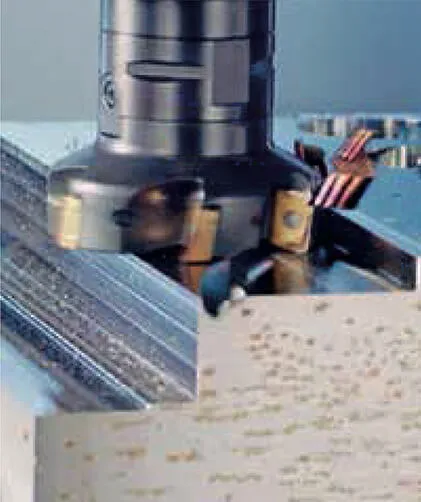

Milling

Due to extremely low residual stresses, Toolox is particularly resistant to distortion when machined with optimal parameters and without introducing unnecessary heat into the workpiece. Long tool life is achieved through clever milling strategies, stable clamping, and always ensuring sufficient chip thickness. Toolox has a unique microstructure that facilitates machining despite its high hardness. Carbides are very hard and wear-resistant microstructural components. The microscopically fine, spherical shape of these carbides in the Toolox microstructure prevents the typical edge damage seen in other tool steels. Sufficiently high tooth feed ensures the removal of carbides along with the chip, while too low a feed would lead to intense abrasive wear on the cutting edge. Sharp cutting edges with positive geometry are ideal for Toolox. Select tools suitable for machining high-alloyed steels. Tools for hard machining (up to 60 HRC) are unsuitable as their cutting edges typically have negative rake angles.

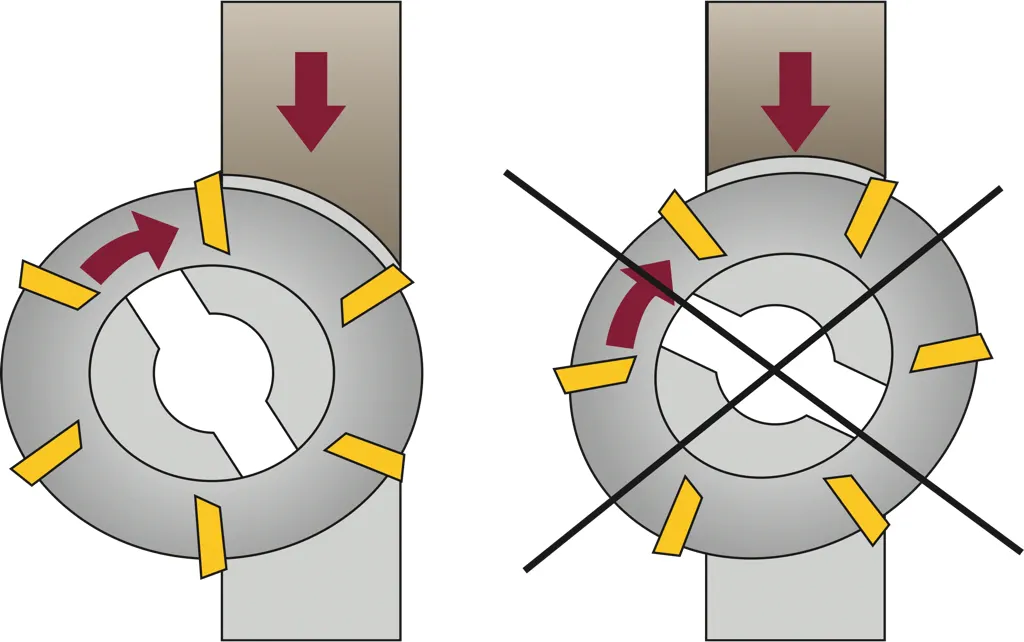

Entry using the "Roll-In" method

Wear after 800 passes

Straight entry into the workpiece

Wear after 390 passes

Introduction to the cutting process using the "Roll-In" method

Face Milling

Intermittent cuts are better milled with round inserts. Particularly high productivity is achieved with HPC (High-Performance Cutting) tools. Also, face mills with corner inserts are suitable for Toolox.

Recommendation for 45° cutters

| Toolox 44 | ||

|---|---|---|

| Cutting Speed: v [m/min] | 120-160 | |

| Feed: fz [mm/tooth] | min. – max. | Starting Value |

| Insert grade P30 | 0.15–0.35 | 0.25 |

Recommendation for Face Mills with Round Inserts

| Toolox 44 | ||

|---|---|---|

| Cutting Speed: v [m/min] | 140-180 | |

| Feed: fz [mm/tooth] | min. – max. | Starting Value |

| Insert grade P30 | 0.10–0.25 | 0.15 |

Recommendation for End Mills / Corner Inserts

| Toolox 44 | ||

|---|---|---|

| Cutting Speed: v [m/min] | 120-160 | |

| Feed: fz [mm/tooth] | min. – max. | Starting Value |

| Insert grade P30 | 0.12–0.25 | 0.17 |

Cutting Data for HPC Copy and Face Milling Cutters

| Material Group | Material Designation | Strength N/mm2 | Copy Milling | Plunge / Bore Circular Milling | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dry Machining | Wet Machining | Dry Machining | Wet Machining | |||||||||||||||

| Preferred Cutting Material | Vc [m/min] | Preferred Cutting Material | Vc [m/min] | Preferred Cutting Material | Vc [m/min] | Preferred Cutting Material | Vc [m/min] | |||||||||||

| min | Start | max | min | Start | max | min | Start | max | min | Start | max | |||||||

| 10.0 | Toolox 44 Hardened Steels |

41-47HRC | F15M | 120 | 160 | 200 | - | - | - | - | F15M | 80 | 105 | 130 | - | - | - | - |

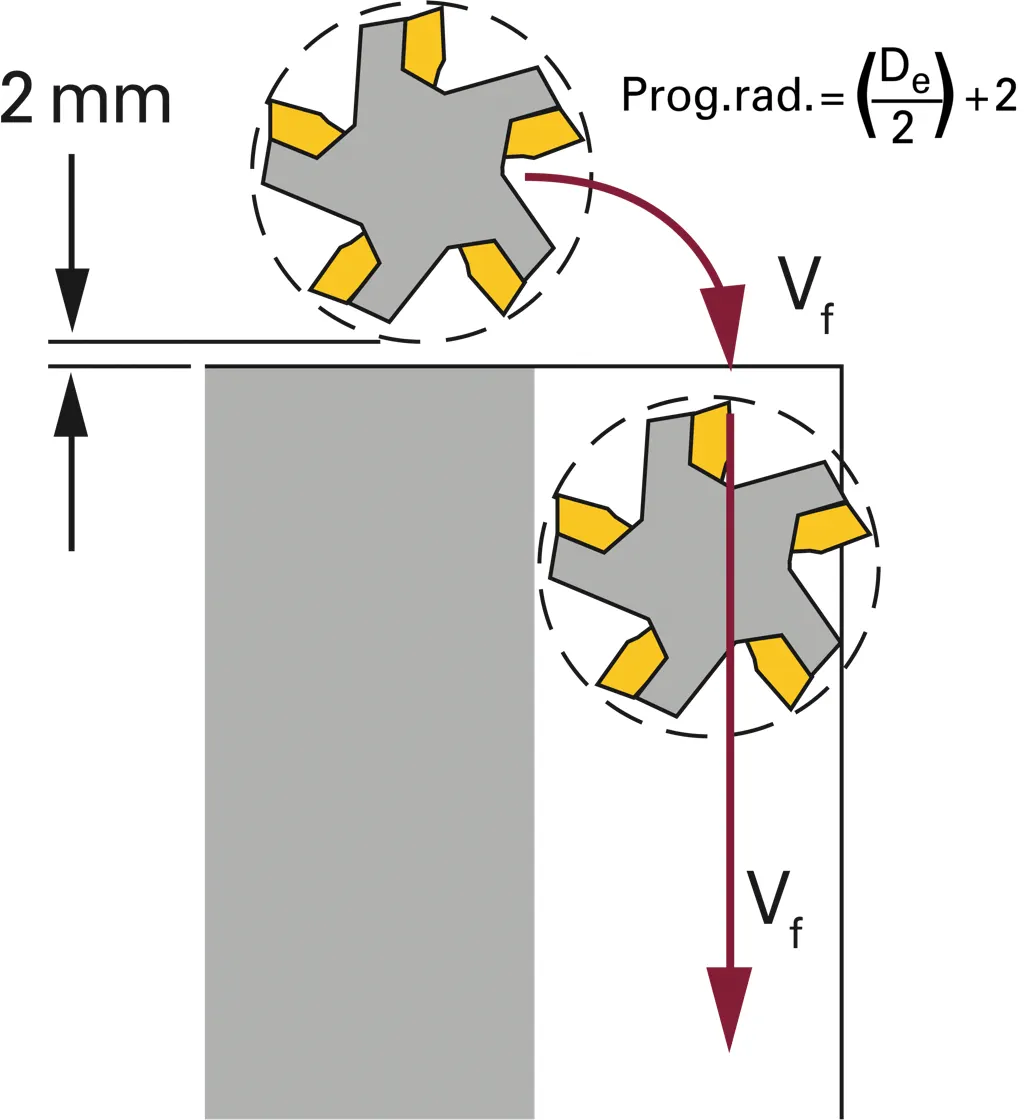

End Milling

When slot milling, a depth of cut ap of 0.5 x D has proven to be effective, and sufficient chip space should be available. End milling up to trochoidal milling is very productive with an ap of the full cutting length and an ae of about 0.1 x D. Dry milling with compressed air cooling to remove chips avoids thermal shock and overload caused by chip recutting.

Threads

Both Toolox materials can be machined with machine taps. Experienced locksmiths drill the core hole slightly larger. Cutting paste, cutting oil, or a richer emulsion have proven to work well.

| Toolox 44 | |

|---|---|

| Cutting Speed: v [m/min] |

3-5 |

| Size | Speed [1/min] |

| M5 | 190-320 |

| M6 | 160-265 |

| M8 | 120-200 |

| M10 | 95-160 |

| M12 | 80-130 |

| M16 | 60-100 |

| M20 | 45-80 |

Thread Milling is a productive process that ensures high manufacturing reliability, even for very small diameters and especially in cases where thread cutting is difficult.

| Toolox 44 | |

|---|---|

| Cutting Speed: v [m/min] |

50-70 |

| Feed: fz [mm/tooth] | 0.02 – 0.05 |

Countersinking as well as chamfering can be easily done on machining centers using indexable insert tools. For less stable machines, countersinks with revolving pilot pins have proven to be effective.

| Toolox 44 | |

|---|---|

| Cutting Speed: v [m/min] |

0.10-0.20 |

| Diameter [mm] | Speed [rpm] |

| 19 | 335-840 |

| 24 | 265–665 |

| 34 | 185–470 |

| 42 | 150–380 |

| 57 | 110–280 |

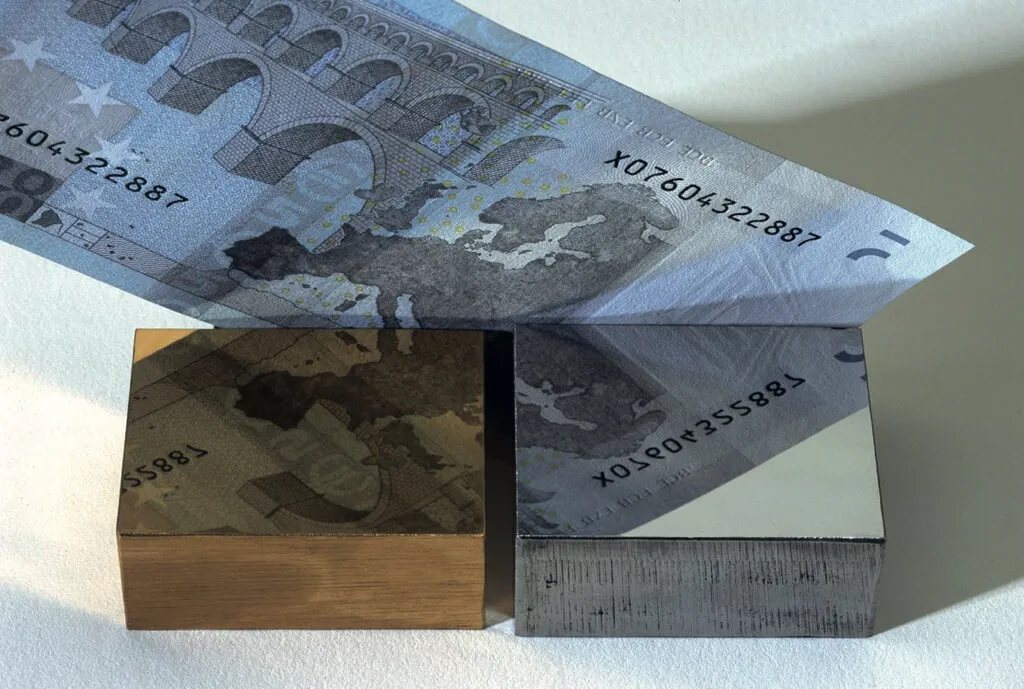

Polishing of Toolox

- Finishing with a coarse abrasive (e.g., grain size 120). All traces of processing or erosion are completely removed. Preferably, use the flat side of the abrasive and vary the grinding direction in an X-pattern to achieve an absolutely flat surface, make your work more efficient, and save time.

- Finishing similar to Step 1 but with a finer grain size, such as 320. All remaining traces from the previous grinding step (Step 1) are completely eliminated.

- Rough polishing with diamond paste on a piece of brass. Grain size 45μm. This rough polishing is performed until all remaining traces and scratches from the previous step (Step 2) are completely removed.

- Proceed as in Step 3, but now use 15μm diamond paste until all remaining traces from Step 3 are gone.

- In this step, follow the procedure from Step 4, but now use 7μm diamond paste. This step is continued until all remaining traces from Step 4 are removed.

- Polish with 7μm diamond paste on a fiber or plastic element. Continue until the last nuances of unevenness remaining from Step 5 are removed.

- Proceed as in Step 6, but instead of 7μm paste, use 3μm diamond paste. Continue until the last nuances of unevenness remaining from Step 6 are removed. (We use the word "nuances" here because the surface is already so flat and fine that there are hardly any visible scratches for the naked eye.)

- Polish with 3μm diamond paste on a piece of felt until all remaining nuances from the previous step are removed.

- As a final step, polish with 3μm diamond paste and cotton. This is a manual process and the final shine is achieved. Continue until the entire surface exhibits a uniform gloss.

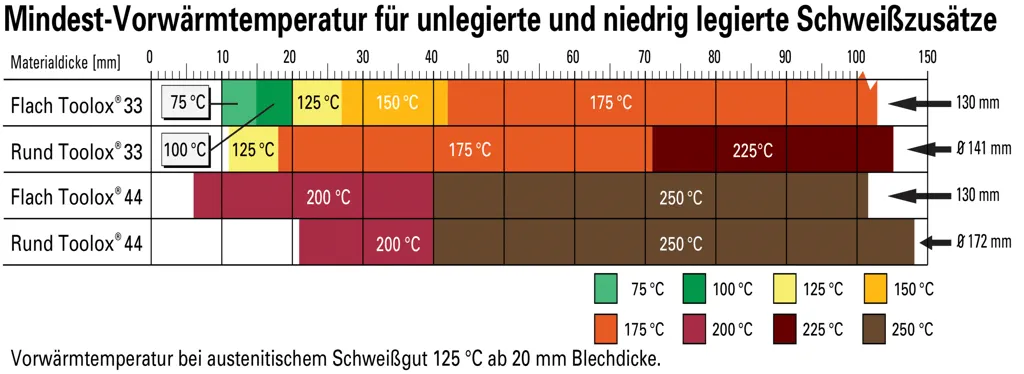

Welding of Toolox

Toolox is weldable with good welding characteristics when following the guidelines below. The carbon

equivalent for Toolox 44 is CEIIW 0.92-0.96 / CET 0.55-0.57.

Austenitic welding additives AWS 307 or AWS 309 are suitable for welding without preheating. This results in

a strength of approximately Rp0.2 = 500 MPa in the weld. Unalloyed or low-alloy

welding additives yield strengths of up to approximately Rp0.2 = 930 MPa and good

toughness.

-

Preheat both sides of the weld seam, about 100-150mm on each side. The preheat temperature should be

reached in the middle of the plate. Maintain the preheat temperature throughout the entire welding

process, especially during tack welding.

- Use preferably soft or stainless electrodes. The electrodes must be dry. The maximum allowable hydrogen content is 5ml/100g of weld material. To achieve optimal texture formation quality, welding should be done using the TIG process with a filler wire having the same chemical composition as the base material. The simplest method is to cut a rod from a leftover part of the base material.

- Weld with a heat input that results in a Δt8/5 value between 10 and 20 seconds.

- For Toolox 44, the interpass temperature should be at most *225°C before welding the next layer.

- Perform post-weld heat treatment in the area of about 100-150mm on each side of the weld seam. The soaking time should be 5 minutes per millimeter of plate thickness or at least 60 minutes. Normally, a soaking time of 2 hours is sufficient. The beginning of the soaking time is the point when the temperature is reached throughout the entire tempering volume.

* Post-weld heat treatment should be conducted at a temperature of 150-200°C if only slight demands regarding shape stability are required.

* Post-weld heat treatment should be conducted at a temperature of 560-580°C if high demands regarding shape stability are required and the influence of the weld seam on the texture formation result should be minimized.

Hardness Comparison Table for Toolox and Hardox

| Tensile Strength MPa |

715 | 790 | 820 | 861 | 935 | 995 | 1,011 | 1,090 | 1,169 | 1,245 | 1,328 | 1,412 | 1,494 | 1,580 | 1,758 | 1,940 | 2,130 |

| Vickers Hardness HV |

205 | 233 | 243 | 261 | 289 | 311 | 317 | 345 | 373 | 401 | 429 | 458 | 485 | 514 | 569 | 627 | 682 |

| Brinell Hardness HBW |

225 | 250 | 260 | 275 | 300 | 320 | 325 | 350 | 375 | 400 | 425 | 450 | 475 | 500 | 550 | 600 | 650 |

| Rockwell Hardness HRC |

19 | 22.5 | 24 | 26 | 29 | 32 | 32.5 | 35.5 | 38 | 40 | 42.5 | 44.5 | 46.5 | 49 | 52.5 | 55 | 57.5 |

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.