1.4112

Steel Glossary

1.4112 X 90 CrMoV 18 (black/green)

Chemical Composition %

| C | Si | Mn | P | S | Cr | Mo | V | |

|---|---|---|---|---|---|---|---|---|

| max. | 0.95 | 1.0 | 1.0 | 0,04 | 0.015 | 19.0 | 1.3 | 0.12 |

| min. | 0.85 | 17.0 | 0.9 | 0.07 |

Heat Treatment

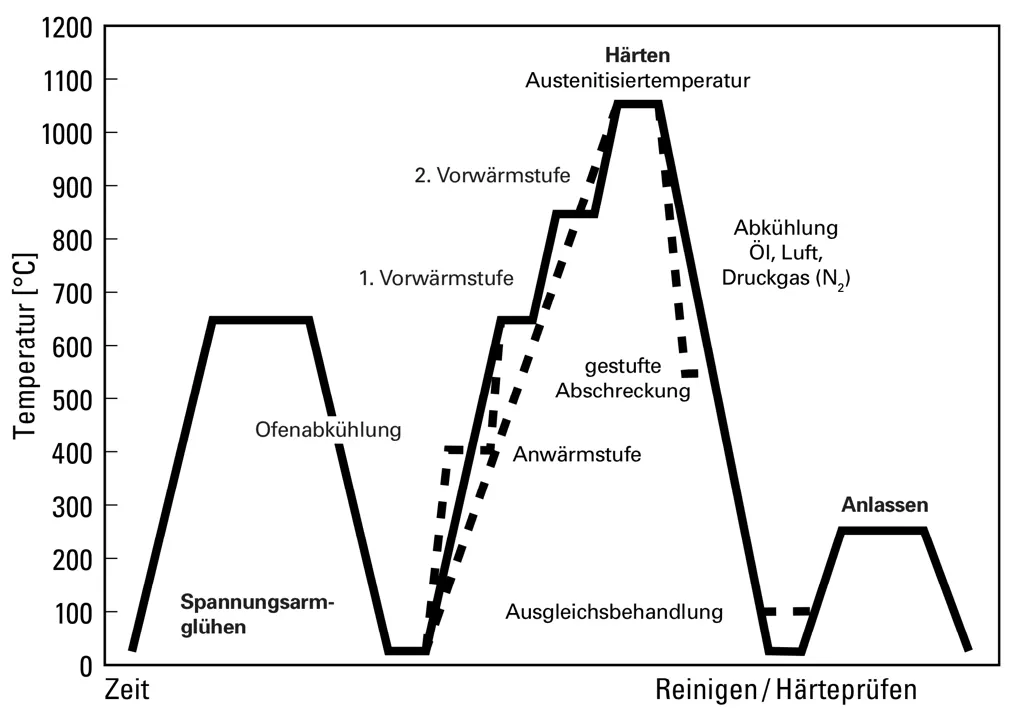

Annealing: 780-840°C, furnace cooling, annealed hardness max. 265 HB

Stress-relief Annealing: 600-650°C, furnace cooling

Quenching/Hardening: 1,000-1,050°C, cooling in oil, compressed gas, air, or warm bath at 500-550°C

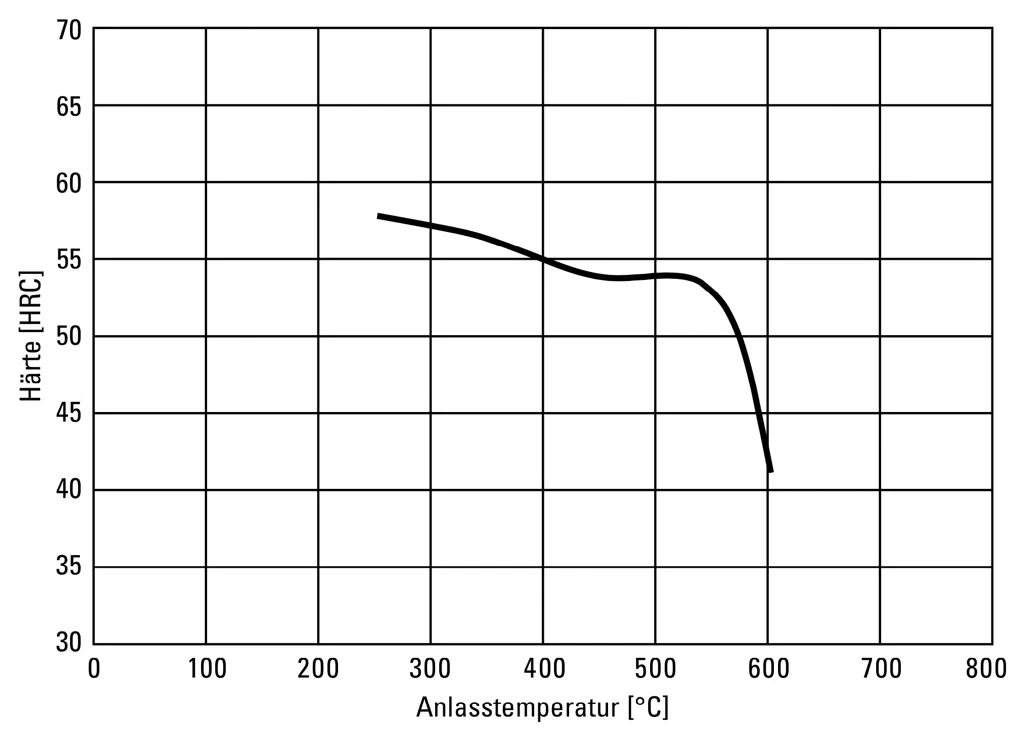

Tempering Diagramm

Hardening Temperature: 1,020°C

Heat Treatment Schedule

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.