Steel Glossary

Daido DRM2

| C | Si | Mn | Cr | Mo | W | V | |

|---|---|---|---|---|---|---|---|

| Typical analysis wt.-% | 0.6 | 0.3 | 0.5 | 5.5 | 2.4 | 1.0 | 1.0 |

| Treatment temperatures | hardness | ||||

|---|---|---|---|---|---|

| Hot forming | Annealing | Hardening | Tempering | Annealed | hardened |

| (please inquire) | 800 - 880°C slow cooling (≤ 20°C/min) |

1,050 - 1,120°C Cooling in oil, gas or salt bath |

550 - 620°C min. 2x tempering, air cooling |

≤ 235 HBW | 58 - 62 HRC |

| Physical properties | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thermal expansion coefficient [10-6/K] | 20 - 100°C | 20 - 200°C | 20 - 300°C | 20 - 400°C | 20 - 500°C | 20 - 600°C | 20 - 700°C | 20 - 800°C |

| 11.0 | 11.4 | 11.8 | 12.1 | 12.3 | 12.6 | 12.4 | 12.9 | |

| Thermal conductivity [W/mK] | 25°C | 200°C | 300°C | 400°C | 500°C | 600°C | 700°C | |

| 23.2 | 26.9 | 27.9 | 29.0 | 28.8 | 29.2 | 29.6 | ||

| 458 | 518 | 555 | 598 | 659 | 756 | 910 | ||

Young's modulus = 210,000 MPa, Specimen hardened at 1,120°C, 2x tempered at 560°C

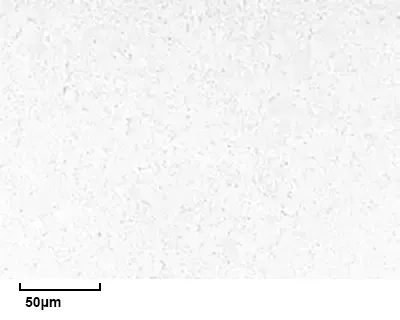

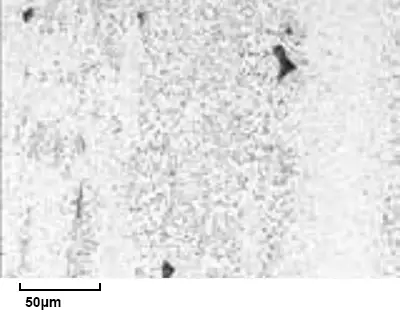

Microstructure

DRM2

(in the center of the bar ∅ 100 mm)

Conventional high-speed steel

(Daido)

Tempering treatment

Specimen: square bar 15 mm, Oil quenching, tempering with air cooling

Impact toughness

Specimens: taken from bar steel, in the center of ∅ 100 mm, U-notched specimen

| Heat treatment | ||

|---|---|---|

| Hardening | Tempering | |

| DRM2 | 1,120°C, oil hardened | 540 - 600°C, double tempered |

| conventional steel | 1,140°C, oil hardened | 540 - 600°C, double tempered |

Fire crack resistance

| Heat treatment | ||

|---|---|---|

| Hardening | Tempering | |

| DRM2 | 1,120°C, oil hardened | 560°C, double tempered |

| 1.3343 | 1,140°C, oil hardened | 580°C, double tempered |

Fatigue strength / Material fatigue

Specimens: from the center of a bar steel ∅ 100 mm

| Heat treatment | ||

|---|---|---|

| Hardening | Tempering | |

| DRM2 (65 HRC) | 1,120°C, oil hardened | 560°C, double tempered |

| conventional steel | 1,120°C, oil hardened | 560°C, double tempered |

| Test method | Wöhler test at room temperature | |

Hardenability

Influence of cooling rate on bending strength

| Heat treatment | ||

|---|---|---|

| Hardening | Tempering | |

| DRM2 | 1,120°C, 200°C/min equivalent to oil hardening |

560°C, double tempered |

Dimensional change during hardening

Specimens: bar steel ∅ 100 mm x 60 mm Length

| Heat treatment | |

|---|---|

| Hardening | |

| DRM2 | 1,120°C, hardened in salt bath |

Drillability

Specimens: bar steel ∅ 100 mm x 60 mm Length

| Heat treatment | |

|---|---|

| Hardening | |

| DRM2 | 1,120°C, hardened in salt bath |

Tempering resistance

Specimens: bar steel ∅ 100 mm x 60 mm Length

| Heat treatment | |

|---|---|

| Hardening | |

| DRM2 | 1,120°C, hardened in salt bath |

Hardening process

Salt bath

Vacuum

Nitriding

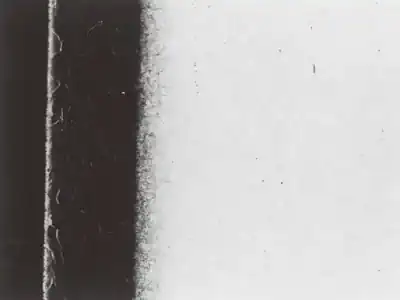

Example of the microstructure of a nitrided surface after the PS process from Daido Amistar.

Hardness distribution after nitriding

The surface hardness reaches here 1.250 HV with NHD = 0,2 mm.

The values given are always representative technical values based on our investigations. Unless otherwise stated, they do not constitute guarantees. Please consult us for individual cases.

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.